Tube-in-tube heat exchangers are a popular option for heat transfer in power plants due to their simple structure and acceptable efficiency. These devices play a crucial role in various processes, including cooling, preheating, steam generation, and energy recovery. Choosing the right tube to tube heat exchanger requires a thorough understanding of operational needs, environmental conditions, and technical requirements for each power plant. This article discusses the key points to consider when selecting this type of heat exchanger, helping engineers and plant managers make informed and optimal decisions.

Introduction to tube in tube heat exchangers and their application in power plants

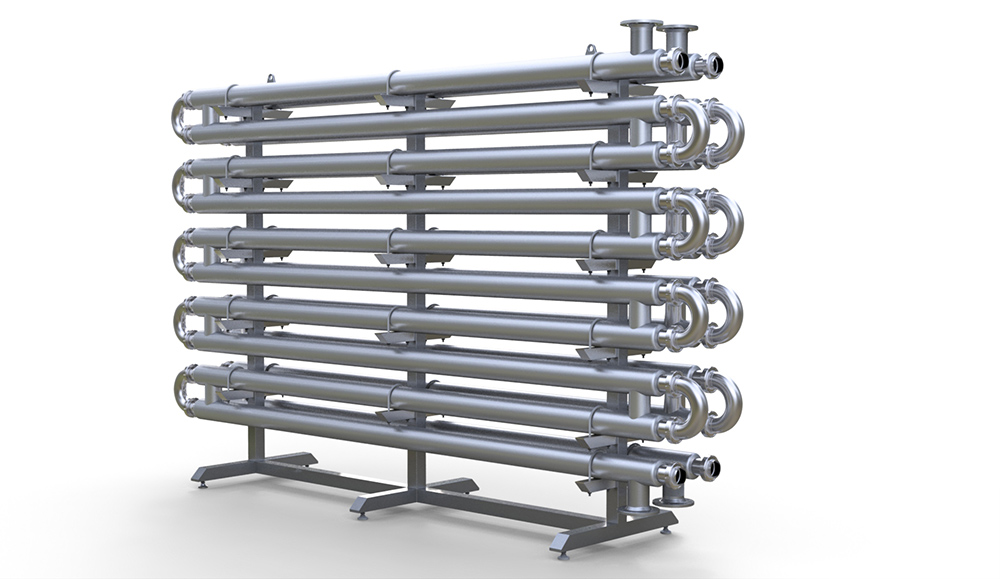

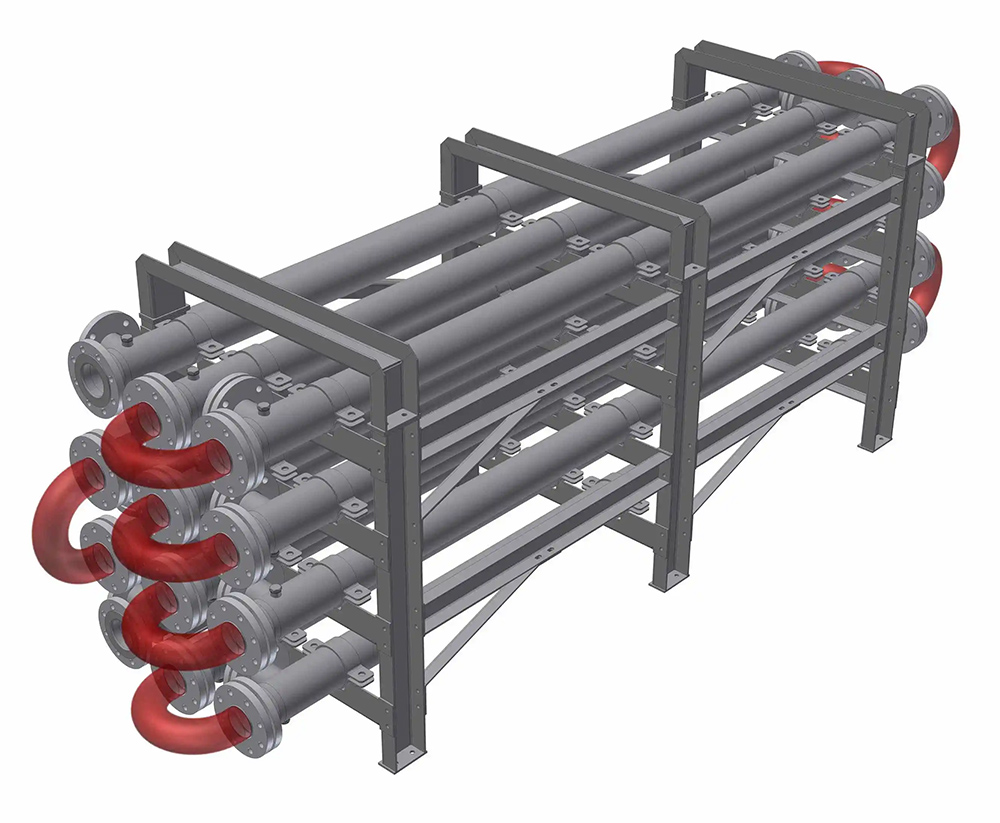

A tube in tube heat exchanger consists of two concentric tubes, with one fluid flowing inside the inner tube and the other in the space between the two tubes. This simple design enables effective heat transfer between the two fluids. In power plants, these exchangers are especially used in oil cooling systems, condensers, and preheaters. Due to their limited heat transfer area, they are generally suited for applications with lower capacity.

The use of tube-in-tube exchangers in power plants is attractive due to their lower design and maintenance costs. However, limitations such as the need for more space and lower efficiency compared to shell and tube or plate heat exchangers restrict their use to specific operational conditions. In thermal and nuclear power plants, they are typically employed in processes that require a relatively small fluid volume for heat transfer.

Key criteria in selecting tube-in-tube heat exchangers

Choosing the right heat exchanger involves evaluating several factors that can directly impact its performance and lifespan. These factors include fluid type, operational temperature and pressure, fluid flow rate, and maintenance requirements, all of which must be carefully considered.

The type of fluid and its properties play a key role in selecting the material of the tubes and the overall design of the heat exchanger. Viscosity, corrosiveness, and the potential for fouling should all be taken into account. For corrosive fluids, materials such as stainless steel or nickel alloys are recommended.

Operational temperature and pressure are also critical factors. In power plants, temperatures can reach up to 600°C and pressures up to 350 bar, so selecting materials that can withstand such extreme conditions is essential.

Flow rate and pressure drop are also important considerations. The design should minimize pressure drop to avoid placing additional load on pumps and other equipment, thereby maintaining the overall system efficiency.

Material selection for tube-in-tube heat exchangers

The material of the tubes and the heat exchanger body directly impacts its performance and durability. Proper material selection should be based on operational conditions, fluid type, and economic requirements.

Corrosion-resistant materials are essential for corrosive environments. Stainless steel, nickel alloys, and titanium are the most common options for these environments. In certain applications, copper or aluminum tubes may also be used, although they offer less resistance to corrosion.

Thermal conductivity and mechanical strength are also important factors in material selection. Materials with high thermal conductivity, such as copper, improve heat transfer but may lack the required mechanical strength for harsh conditions. Conversely, alloy steels offer high strength but lower thermal conductivity.

Cost and availability of materials should also be considered. Selecting materials that strike a balance between performance and cost is crucial for power plant projects.

Optimized design for enhanced efficiency

Proper design of the tube to tube heat exchanger plays a significant role in improving heat transfer efficiency and reducing operational costs.

Selecting the right flow pattern between fluids is critical. Counterflow typically offers higher thermal efficiency due to the greater temperature difference between the inlet and outlet fluids.

Increasing the heat transfer surface area by using fins or corrugated tubes can significantly improve efficiency, especially when one of the fluids is a gas.

Minimizing fouling is also important. The design should ensure smooth surfaces and easy cleaning to reduce the accumulation of deposits, maintaining long-term efficiency.

Standards and power plant requirements

Adhering to international standards for the design and construction of heat exchangers in power plants is mandatory to ensure safety, performance, and compliance with environmental regulations.

The TEMA standard serves as the primary reference for tube heat exchanger design, specifying requirements for material selection, fabrication methods, and performance testing. The Pressure Equipment Directive (PED) also applies to pressure equipment in Europe and must be followed in international projects.

In addition, environmental requirements must be considered. Heat exchangers should be designed to minimize fluid leakage and reduce negative environmental impacts.

Corrosion management and maintenance

Corrosion is one of the most significant factors affecting the lifespan of heat exchangers in power plants. Proper corrosion management and routine maintenance programs can significantly extend the life of these devices.

Galvanic corrosion, caused by the contact between dissimilar metals, is a common issue. Selecting compatible materials and using chemical inhibitors can help control this type of corrosion.

Maintenance planning should include regular cleaning, inspections for leaks, and pressure testing to ensure system integrity. Tube in tube heat exchangers, with their simple structure, are easier to maintain compared to other types of exchangers.

Using corrosion-resistant coatings is also an effective solution for extending the life of the heat exchanger, especially in corrosive environments.

Economic considerations in selecting tube in tube heat exchangers

Initial and operational costs play a decisive role in selecting tube-in-tube heat exchangers. The right choice should balance cost and performance to make the project economically viable.

Initial costs include the purchase price of the heat exchanger, installation costs, and space requirements. Tube-in-tube exchangers typically have lower fabrication and installation costs compared to shell-and-tube or plate exchangers, which can be a significant advantage in budget-constrained projects.

On the other hand, operational costs, such as energy consumption for pumping fluids, periodic maintenance, and performance degradation, should also be considered. Optimal design, proper material selection, and preventive maintenance programs can reduce operational costs and accelerate the return on investment. Ultimately, heat exchangers that offer high efficiency and require less maintenance provide faster returns for power plants.

Environmental conditions affecting tube in tube heat exchanger selection

The environmental conditions of the installation site can have a significant impact on the performance and longevity of the heat exchanger. Factors such as ambient temperature, humidity, chemical presence in the air, and available space for installation need to be carefully assessed.

In areas with high ambient temperatures, heat exchangers must be able to withstand the additional heat and maintain efficiency. A smaller temperature difference between the hot fluid and the surrounding air may reduce heat transfer efficiency, requiring more precise design and material selection.

High humidity and the presence of corrosive substances in the air can increase the risk of corrosion. In such conditions, using corrosion-resistant materials and applying protective coatings is essential to prevent gradual degradation of the heat exchanger.

Limited installation space is also a critical factor in selecting the type of heat exchanger. Due to their linear design, tube-in-tube exchangers require more space compared to plate or shell and tube heat exchangers, which may be a disadvantage in power plants with space constraints.

Role of tube in tube heat exchangers in energy optimization

Optimizing energy consumption is one of the main goals in designing power plant thermal systems, and tube-in-tube heat exchangers can play a significant role in this process.

By recovering heat from the hot effluent fluids, these heat exchangers can help preheat incoming fluids. Heat recovery reduces energy consumption, improves the overall efficiency of the plant, and consequently lowers fuel costs.

Improved heat transfer efficiency also leads to a reduction in greenhouse gas emissions produced by power plants, helping to achieve better environmental targets.

The flexible design of tube-in-tube heat exchangers allows them to be integrated into various power plant systems, including combined cycles and heat recovery systems, enhancing the efficiency of thermal systems.

Challenges and limitations of tube in tube heat exchangers

Despite their numerous advantages, tube-in-tube heat exchangers have limitations that should be considered during the selection and design process.

The primary limitation is their relatively low heat transfer area. Due to the simple structure, the contact surface area between fluids is limited, making them unsuitable for processes that require very high heat transfer.

The need for more space is another challenge. The linear design of these heat exchangers requires more space compared to plate or shell-and-tube exchangers, which could be a disadvantage in modern power plant projects with limited space.

Moreover, these exchangers are sensitive to fouling. If the fluids have a tendency to form deposits, frequent cleaning will be required, which can increase operational costs and, if neglected, result in reduced efficiency and equipment lifespan.

Innovations in tube in tube heat exchanger design

Recent advancements in design and construction technologies have improved the performance of tube-in-tube heat exchangers, leading to their use in more applications.

One of these advancements is the use of nanoscale coatings on the internal surfaces of the tubes, which increases resistance to corrosion and fouling, thereby improving the life and efficiency of the heat exchanger.

Modular designs have also facilitated quicker installation, maintenance, and replacement of heat exchangers. This feature is particularly important in power plants that require short downtimes.

Advanced simulation software such as CFD enables the prediction of fluid behavior and heat transfer before the heat exchanger is built, leading to more optimized designs, lower testing costs, and greater accuracy in predicting the exchanger’s performance.

Practical recommendations for selecting tube in tube heat exchangers in power plants

To optimize the selection of tube-in-tube heat exchangers in power plants, several key recommendations can help with better decision-making. Accurate evaluation of project needs is the first step. Defining fluid type, temperature, pressure, flow rate, and environmental constraints should be done before selecting the heat exchanger.

Consultation with specialists and reputable manufacturers can ensure a more precise and informed choice. This collaboration can help avoid costly mistakes and identify the best option for the specific conditions of the power plant.

Conducting tests and simulations before final installation can assist in more accurately predicting the heat exchanger’s performance under real-world conditions and reduce the likelihood of unexpected issues in later stages.

Conclusion

Selecting a tube-in-tube heat exchanger for a power plant is a complex, multifaceted process that requires careful consideration of technical, economic, and environmental factors. By taking into account characteristics such as fluid type, operational temperature and pressure, material selection, optimal design, and adherence to international standards, a heat exchanger can be chosen that provides not only high efficiency but also low costs and long lifespan.

The use of advanced technologies and consideration of specific environmental conditions can enhance the performance of the heat exchanger and extend its service life. Ultimately, a thorough assessment of needs, consultation with experts, and the use of modern design tools are key to the successful selection and optimization of heat exchangers in power plants.

References

- ASME Boiler and Pressure Vessel Code, Section VIII: Rules for Construction of Pressure Vessels

- API Standard 650: Welded Tanks for Oil Storage

- ASTM International Standards for Materials

- Pressure Vessel Design Manual by Dennis R. Moss

- CASTI Guidebook to ASME Section VIII

- Engineering Toolbox on Pressure Vessel Design

- TWI Global FAQs on Pressure Vessels

- Petroleum Training on Pressure Vessel Design