In the petrochemical and thermal process industries, heat exchangers play a vital role in transferring energy between fluids. One of the simplest yet most efficient types of these devices is the double pipe heat exchanger, which, due to its concentric tube structure, is suitable for small to medium-scale applications. However, like any other industrial equipment, these exchangers face certain challenges that can affect their performance. Common problems include fouling, corrosion, and leakage, which—if not addressed promptly—can lead to operational shutdowns and high maintenance costs.

At Petrosazeh Beinolmelal Aram Co. (Petrosazeh), a company specialized in the design and fabrication of petrochemical equipment, the focus is on the early detection of these issues and providing practical solutions so that users can achieve maximum efficiency from their systems. This article provides a comprehensive analysis of the most common problems in double pipe heat exchangers and proposes solutions based on global industrial experience.

Understanding the Double Pipe Heat Exchanger and Its Applications

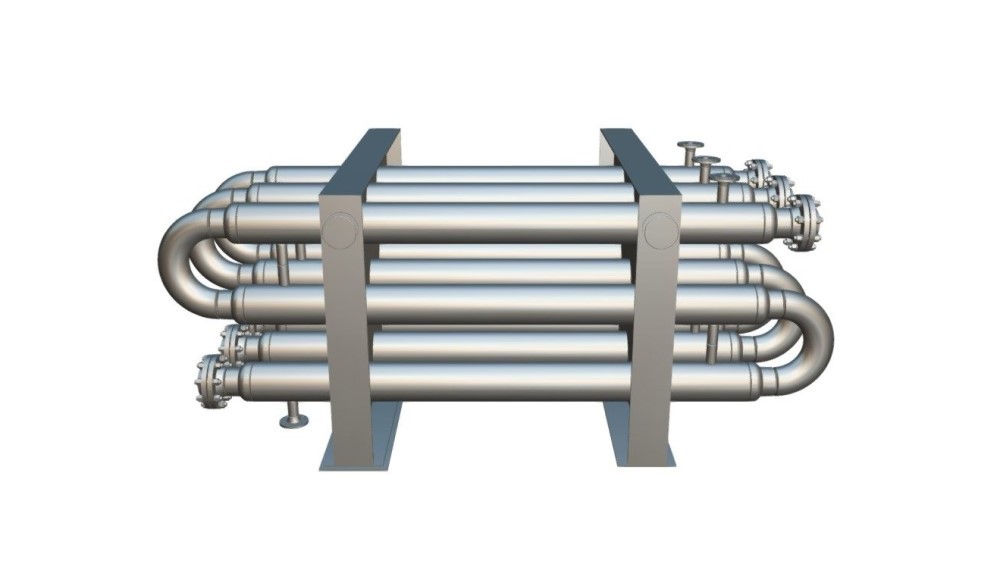

A double pipe heat exchanger consists of two concentric pipes—one fluid flows through the inner pipe while the other flows through the annular space between the two pipes. This simple design allows for either parallel flow or counterflow and is ideal for heat transfer between fluids with moderate temperature differences. Compared to more complex designs such as shell and tube exchangers, this type is less expensive and easier to install, though it offers lower heat transfer capacity.

Beyond its simplicity, the double pipe heat exchanger is widely used in applications such as oil cooling in hydraulic systems or water heating in chemical processes. Petrosazeh uses corrosion-resistant materials such as stainless steel in its designs to ensure longer service life. However, understanding the structure is essential, as common problems often arise from the interaction between fluids and the internal surfaces.

Ultimately, the choice of this type of exchanger depends on the specific process requirements. For example, in low-flow applications, this design is highly efficient, but in large-scale operations, several parallel units may be required to achieve the desired performance.

Read more: What is double pipe heat exchanger and its role in refineries

Fouling and Blockage in Double Pipe Heat Exchangers

Fouling is one of the most common issues in double pipe heat exchangers. It occurs when suspended solids, mineral deposits, or biological materials accumulate on the inner surfaces of the pipes. This problem is particularly common with fluids containing high levels of impurities such as seawater or chemical solutions and leads to a reduction in the overall heat transfer coefficient. Consequently, the system consumes more energy to maintain the desired temperature and experiences increased pressure drop.

In severe cases, fouling can cause complete flow blockage, especially in the inner tube where space is limited. Studies indicate that in industries such as oil refining, fouling can reduce efficiency by up to 20%. Monitoring inlet and outlet pressure differences helps detect this problem early.

Preventive solutions include installing inlet filters to remove suspended particles and performing chemical cleaning with mild acids or mechanical brushing. In modern designs, anti-fouling coatings on internal surfaces can significantly reduce deposit formation and extend the exchanger’s service life.

Corrosion and Material Degradation in Double Pipe Heat Exchangers

Corrosion, caused by chemical reactions between the process fluids and the tube materials, is another major challenge. In tube to tube heat exchangers, corrosion may appear as uniform corrosion or localized pitting, leading to reduced wall thickness and eventual failure. Contributing factors include low pH, high temperature, and the presence of chloride ions, common in marine or chemical environments.

This not only weakens the structure but can also cause leakage and fluid contamination. For example, in petrochemical processes, internal corrosion can generate unwanted by-products that disrupt the operation.

Prevention strategies include controlling the fluid chemistry with corrosion inhibitors, conducting periodic non-destructive inspections (such as ultrasonic testing), and applying epoxy or ceramic coatings to create a protective barrier between the fluid and the metal surface.

In advanced cases, replacement of damaged sections may be necessary, though preventive maintenance can minimize costs. Global experience shows that online corrosion monitoring systems provide early warnings and prevent equipment failure.

Leakage and Sealing Problems

Leakage in tube to tube heat exchangers often originates from joints, welds, or damaged walls and can cause cross-contamination of fluids. This problem intensifies under high pressure or temperature fluctuations, threatening process safety. Early signs include pressure loss or discoloration of outlet fluids.

External leaks can pollute the environment, while internal leaks degrade product quality. Petrosazeh employs high-quality welding techniques to minimize such risks, though external factors such as vibration may still cause leaks.

To address this, regular pressure testing (e.g., hydrostatic tests) and the use of temperature- and pressure-resistant seals (such as Viton O-rings) are recommended. For minor leaks, welding repairs or plugging may suffice, but full replacement of the damaged section is often the safest solution.

Vibration and Mechanical Stresses

Fluid-induced vibration, particularly at high velocities, can cause material fatigue and cracking in double pipe exchangers. This problem is more frequent in the inner tube, where turbulent flow occurs, and can be amplified by connected pumps.

In addition to structural damage, vibration generates noise and reduces efficiency. Engineering studies show that excessive fluid velocity can lead to flow-induced vibration, significantly shortening equipment lifespan.

Pressure Drop and Flow Problems

Excessive pressure drop often results from fouling or poor design and increases pump energy consumption. In the annular space between pipes, uneven flow distribution can create stagnant zones that exacerbate fouling.

This reduces overall system efficiency and can cause overheating. In industrial applications, unbalanced pressure drop may halt the process and raise operating costs. Solutions include optimizing pipe diameters and increasing flow area.

Regular cleaning and installation of flow distributors can help achieve uniform flow. Advanced designs employ corrugated tubes, which enhance turbulence without excessive pressure loss—thus improving heat transfer while maintaining energy efficiency.

Thermal Stresses and Temperature Shock

Thermal stresses occur due to differential expansion between inner and outer tubes, potentially causing cracks. In double pipe heat exchangers, thermal shock is common during startup or shutdown, placing stress on the materials.

This problem is aggravated when fluids have large temperature differences, posing safety risks. Warning signs include unusual noises or visible deformation. Solutions include gradual heating during startup and using materials with similar thermal expansion coefficients.

Temperature monitoring with thermocouples can provide early warnings. In severe cases, redesigning the system using nickel-based alloys or other high-resistance materials may be necessary.

Improper Material Selection and Design Errors

Choosing unsuitable materials can lead to premature failure, especially in corrosive or high-pressure environments. Poor design can also cause uneven flow distribution and reduced performance.

Such issues usually stem from neglecting actual operating conditions and result in higher repair costs. To prevent them, a detailed analysis of process fluids and conditions following ASME standards is essential. Additionally, simulation and prototype testing can help identify potential problems before installation.

Read more: Considerations in choosing tube in tube heat exchangers

Importance of Preventive Maintenance

Preventive maintenance, including regular inspections, cleaning, and monitoring of operational parameters, is crucial to avoid major failures in double pipe heat exchangers. This proactive approach reduces costs and minimizes downtime.

Innovations in Double Pipe Heat Exchanger Design

Recent innovations—such as the use of modern turbulators in the annular space—have significantly improved heat transfer performance. These devices disturb the flow, increasing turbulence and reducing boundary layer thickness, leading to up to a 40% increase in heat transfer coefficient.

Studies show that 3D turbulators optimize performance in both heating and cooling without significant pressure drop increase. Additionally, helical or coiled tubes in advanced designs extend the flow path, enhancing fluid contact and thermal performance—an approach also used in aerospace compact exchangers.

Nanocoatings and composite materials are also key innovations. For example, graphene-based coatings create smoother surfaces, reduce friction, and enhance resistance to corrosion and fouling. These advancements not only address traditional issues but also lower energy consumption and comply with environmental standards.

Furthermore, active enhancement techniques, such as magnetic fields or controlled vibrations, have been explored to intensify heat transfer. These emerging technologies can potentially reduce equipment size, making them ideal for space-limited applications.

Conclusion

Common problems in double pipe heat exchangers—ranging from fouling and corrosion to thermal stresses—can be effectively managed through proper technical knowledge and preventive maintenance. Understanding these challenges and implementing proactive measures not only improves safety but also enhances the economic efficiency of processes.

Petrosazeh is committed to providing high-quality, durable equipment and supports users by focusing on robust designs and innovative solutions that maximize the return on investment.

Investing in innovation and preventive maintenance ensures long-term performance and minimizes operational risks. Ultimately, with advancing technology, the future of double pipe heat exchangers looks promising, empowering industries to meet new challenges such as climate change and complex process fluids with confidence.

References:

- https://microcoils.in/common-heat-exchanger-problems-and-how-to-solve-them/

- https://www.tubotechinc.com/blog/double-pipe-heat-exchanger-vs-shell-and-tube.html/

- https://engitech.in/ultimate-guide-to-double-pipe-heat-exchangers/

- https://pragyaassociates.net/top-10-common-heat-exchanger-issues-and-how-to-avoid-them/

- https://www.everheatexchanger.com/article/top-7-heat-exchanger-failures-and-how-to-prevent-them.html/

- https://www.heatexchangerguy.com/common-failures-in-shell-tube-heat-exchangers/

- https://www.enerquip.com/3-types-of-mechanical-failures-in-shell-and-tube-heat-exchangers-and-how-to-prevent-them/

- https://heat-exchanger-world.com/troubleshooting-tips-for-tubular-heat-exchangers/

- https://coolingbestpractices.com/system-assessments/cooling-controls/heat-exchanger-problem-causes-and-troubleshooting/