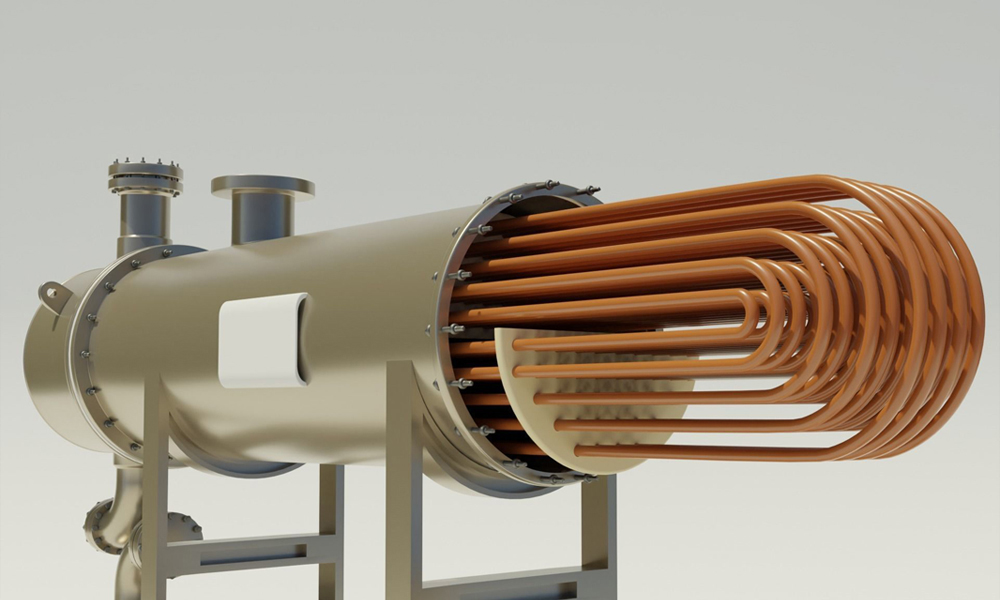

In the oil and gas refining industry, optimizing heat transfer directly affects energy consumption and overall efficiency. The shell and tube heat exchanger is one of the most crucial pieces of equipment in this regard. Improving its heat transfer coefficient can increase process capacity and reduce equipment size.

Petrosazeh Beinolmelal Aram Co. (Petrosazeh), utilizing modern designs and international standards, offers effective methods to enhance the heat transfer coefficient, helping clients improve efficiency, process stability, and cost-effectiveness. The following sections review practical and advanced approaches that enhance the performance of shell and tube heat exchangers.

Importance of Enhancing the Heat Transfer Coefficient in Shell and Tube Heat Exchangers

The heat transfer coefficient is a measure of the rate of heat exchange between fluids; increasing it leads to lower energy consumption and improved overall efficiency. In processes such as crude oil distillation, a low heat transfer coefficient can result in higher fuel requirements and increased operating costs.

Through advanced engineering designs, Petrosazeh improves the heat transfer coefficient to provide clients with more efficient equipment and cost-effective processes. This enhancement also helps reduce pollutants, as lower energy use leads to fewer greenhouse gas emissions. In harsh industrial environments, improving the heat transfer coefficient extends equipment life and minimizes maintenance. For instance, a 20% improvement can lead to thousands of hours of stable, uninterrupted operation.

Using Advanced Baffles to Improve Flow

One effective approach is replacing conventional baffles with helical (spiral) baffles, which guide the fluid flow in a rotational manner, increasing turbulence and eliminating stagnant layers to boost heat transfer.

Helical baffles promote uniform flow, reduce pressure drop, and minimize fouling, improving the heat transfer coefficient by up to 30%.

- Perforated baffles: Generate higher turbulence and ensure better flow distribution.

- Rod baffles: Control tube vibration and enhance system safety.

Selecting the right baffle type requires flow analysis to balance the trade-off between pressure drop and heat transfer efficiency.

Using Enhanced-Surface and Finned Tubes

Corrugated or dimpled tubes increase the heat transfer coefficient passively by creating internal turbulence and expanding the effective surface area.

- Finned tubes: Increase surface contact and are especially effective on the shell side or in gas flows.

- Nanocoated tubes: Improve thermal conductivity and corrosion resistance.

Combining advanced tubes with optimized baffles produces a synergistic effect, significantly boosting heat transfer without introducing excessive pressure drop.

Installing Inserts and Turbulators Inside Tubes

Inserts, such as twisted tapes, disrupt the laminar flow and enhance turbulence, thus improving heat transfer. This method is both cost-effective and efficient, capable of increasing the coefficient by up to 40% in laminar flow regimes.

Turbulators break stagnant layers and reduce fouling in viscous fluids. Additionally, using inserts on the shell side can decrease pumping energy.

Petrosazeh utilizes simulation tools to determine the optimal insert design based on fluid viscosity, maximizing the heat transfer coefficient without causing excessive pressure increase.

Active Methods: Bubble Injection and Mechanical Vibration

- Bubble injection: Introducing bubbles into the shell side promotes turbulence and can increase the heat transfer coefficient by up to 20%, breaking stagnant layers and enhancing thermal performance.

- Mechanical tube vibration: Reduces fouling and maintains a stable heat transfer rate but requires additional energy input. Low-frequency vibrations offer the best results.

Combining these active techniques with passive methods, such as helical baffles, creates a synergistic effect that greatly improves exchanger performance. Although these methods involve higher initial costs, they yield long-term benefits and energy savings.

Reducing Fouling and Implementing Periodic Cleaning

Fouling significantly decreases the heat transfer coefficient. Applying anti-fouling coatings, performing periodic chemical cleaning, and adding anti-fouling agents to the process fluid are effective ways to maintain performance.

- Anti-fouling coatings: Repel particles and improve heat transfer efficiency.

- Regular cleaning: Keeps the heat transfer coefficient close to its original value and prevents production downtime.

- Sensor-based monitoring: Detects fouling early, allowing preventive maintenance actions.

Design Optimization and Material Selection

- High-conductivity materials: Advanced alloys increase the heat transfer coefficient.

- Reduced wall thickness: Improves heat transfer, provided structural integrity is maintained.

- Increased number of passes: Optimizes flow distribution and enhances heat transfer.

Engineering simulations help identify the best design combination to maximize heat transfer without excessive pressure loss.

Read more: Guide to shell and tube heat exchangers design

Future Developments in Heat Transfer Enhancement

- Smart materials: Adapt to temperature variations and optimize heat transfer automatically.

- Artificial intelligence: Enables self-adjusting heat exchangers for continuous optimization.

- Nanofluids: Improve thermal conductivity and overall exchanger performance.

These innovations will revolutionize the future of energy efficiency and process performance in the refining industry.

Read more: Design Standards for Shell and Tube Heat Exchangers (TEMA – ASME)

Conclusion

Enhancing the heat transfer coefficient in shell and tube heat exchangers leads to improved performance, lower energy consumption, and longer equipment lifespan. Petrosazeh, through advanced equipment and customized engineering solutions, supports clients in achieving higher efficiency and reduced operational costs. For consultation or more information, please contact our technical experts.

References:

- heat-exchanger-world.com/get-more-out-of-your-heat-exchangers-with-heat-transfer-enhancement-part-2-enhancement

- stalwartint.com/unveiling-the-strategies-for-peak-heat-exchanger-performance

- intechopen.com/chapters/82664

- alfalaval.com/globalassets/documents/microsites/heating-and-cooling-hub/alfa_laval_heating_and_cooling_hub_the_theory_behind_heat_transfer.pdf

- innovationinfo.org/articles/SJASR/SJASR-6-168.pdf

- epj-conferences.org/articles/epjconf/pdf/2015/11/epjconf_efm2014_02119.pdf

- hcpetroleum.hk/news-detail/182

- sciencedirect.com/science/article/pii/S001793102400320X