Cylindrical tanks play an essential role in various industries, particularly in the oil, gas, chemical, and petrochemical sectors. Cylindrical tanks come in two main types: fixed-roof and floating-roof. Commonly used for storing chemicals, crude oil, and petroleum products, each tank type is selected based on its specific application. In this article, we will explore and compare these two types of cylindrical tanks.

Fixed-Roof Cylindrical Tanks

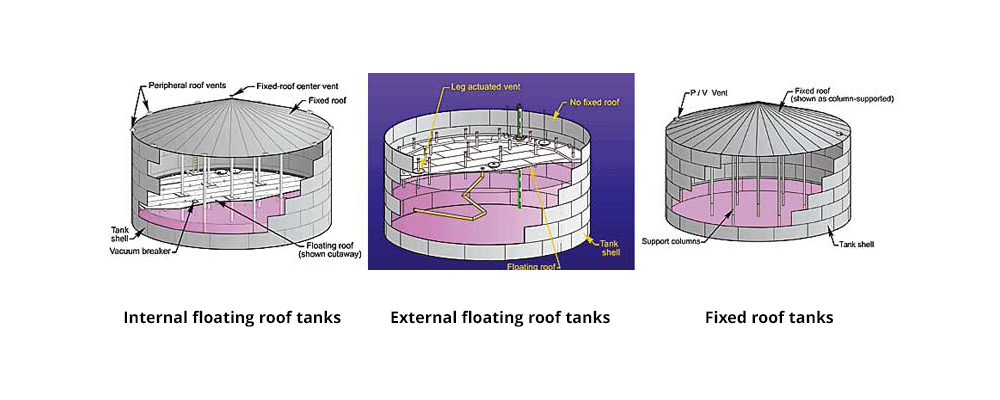

Fixed-roof cylindrical tanks are among the most widely used storage tanks, primarily designed for storing low-pressure liquids and gases. These tanks consist of a cylindrical body with a fixed roof welded to the walls, thus being known as fixed-roof tanks.

Applications and Features of Fixed-Roof Tanks

Fixed roof tanks are commonly used to store chemicals and products with minimal evaporation or those that do not require special containment. They are ideal for storing materials like water, some petrochemical products with lower boiling points, and low-reactivity chemicals. Since their roof is fixed, there is potential for vapor release into the environment, making them unsuitable for high-evaporation materials or substances that need to be stored in airtight conditions.

Advantages of Fixed-Roof Tanks

With a simpler structure that requires no complex roof movement mechanisms, these tanks are more cost-effective to build and maintain compared to floating roof tanks. Their permanently attached roof makes them more stable against wind and weather conditions. Additionally, the lack of moving parts reduces the need for regular maintenance compared to floating-roof tanks.

Floating-Roof Cylindrical Tanks

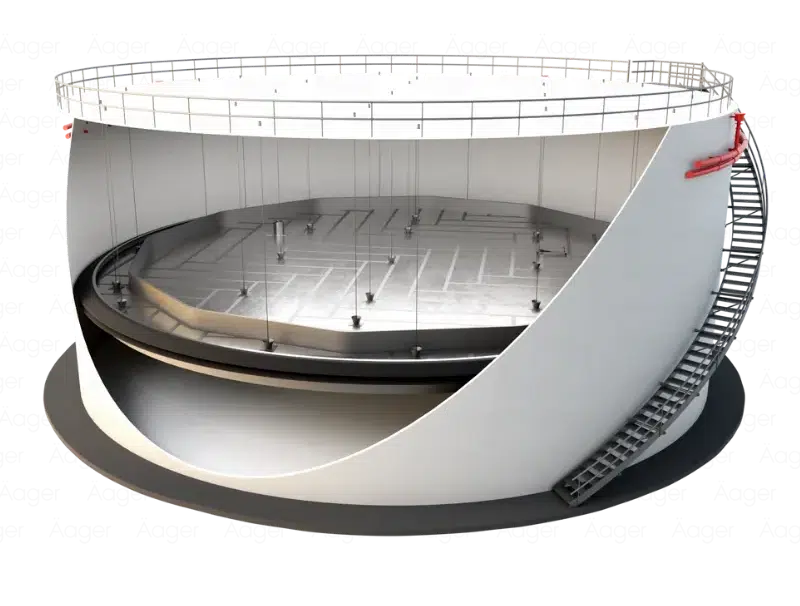

In floating-roof cylindrical tanks, the roof floats on the liquid’s surface, moving up or down with the liquid level. This design is ideal for highly volatile substances like gasoline, crude oil, and light petroleum products. Floating-roof tanks significantly reduce liquid evaporation by minimizing the air gap between the roof and the liquid surface.

Features of Floating-Roof Tanks

Floating-roof tanks are categorized into internal and external floating roofs. The internal floating roof is placed within a fixed tank shell, preventing the entry of water and external contaminants. The external floating roof rests directly on the liquid, moving along with the liquid’s surface level.

Advantages of Floating-Roof Tanks

Due to their design, which keeps the roof in constant contact with the liquid surface, floating-roof tanks reduce material evaporation and prevent vapor emissions into the environment. They are also safer, as reduced headspace helps control vapor pressure. This design lessens the need for advanced cooling and vapor control systems by reducing excessive evaporation.

Key Differences Between Fixed-Roof and Floating-Roof Tanks

Type of Stored Material: Fixed-roof tanks are more suitable for low-evaporation substances or those that do not require protection from air exposure, while floating-roof tanks are ideal for high-evaporation materials.

Construction and Maintenance Costs: Fixed-roof tanks are simpler and more affordable to construct and maintain, whereas floating-roof tanks are more costly due to the floating roof mechanism and sealing systems.

Vapor Emission Control: Floating-roof tanks, with their direct roof-liquid contact, produce fewer vapors and are better suited for storing high-evaporation materials.

Safety Considerations for Using Fixed-Roof and Floating-Roof Tanks

Certain safety measures are necessary for both tank types. For fixed-roof tanks, proper ventilation systems are essential to reduce vapor pressure in the space above the liquid. For floating-roof tanks, ensuring the integrity of roof seals is crucial to prevent contamination from entering the tank.

Conclusion

Both fixed-roof and floating-roof cylindrical tanks have unique characteristics that make them suitable for specific applications based on the stored material, environmental conditions, and budget. Fixed-roof tanks, with simpler structures and lower construction and maintenance costs, are suitable for materials with low volatility. Floating-roof tanks, offering greater vapor control, are preferred for volatile materials but come at a higher construction and maintenance cost.

As a reputable manufacturer in this field, Petrostructure Company leverages advanced technology and high-quality materials to produce tanks that meet international standards, ideal for storing oil, chemicals, and other industrial products. For consultation and order placement, contact our experts at Petrosazeh.