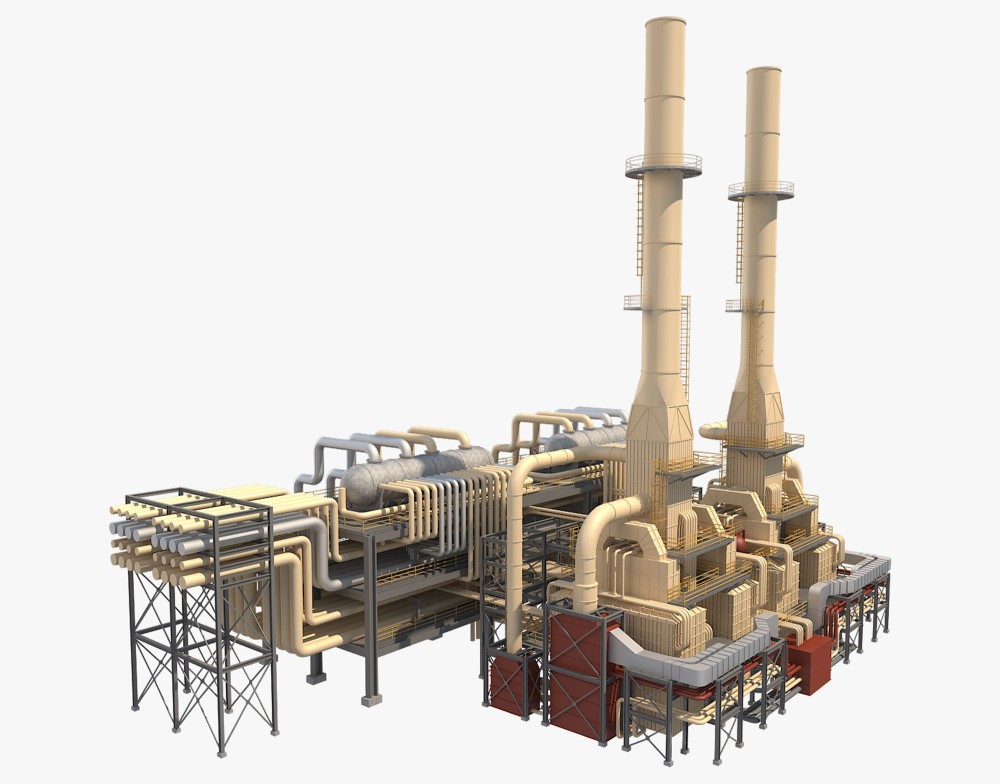

Furnaces are among the vital equipment used in the oil and gas industry, serving essential roles in processes such as heating, evaporation, cracking, and other thermal operations. The standards governing the design, construction, and operation of these furnaces play a key role in enhancing safety, efficiency, and refinery equipment longevity.

The purpose of developing furnace standards is to ensure safe and efficient performance under harsh operational conditions. These standards cover design requirements, material selection, construction, installation, inspection, and maintenance. Given the complexity of refinery and petrochemical processes, adherence to these standards not only helps reduce environmental hazards and improve safety but also optimizes operational costs.

Importance of Furnace Standards in the Oil and Gas Industry

Standards serve as a common language between manufacturers, engineers, and operators, ensuring furnaces can withstand high temperatures, intense pressures, and corrosive chemicals. Proper implementation of these standards prevents incidents such as explosions, gas leaks, and equipment failures. In addition to improved safety, furnace standards play a significant role in enhancing energy efficiency.

Refinery and petrochemical furnaces are among the main energy consumers in the oil and gas industry. Designing in accordance with standards like API 560 can reduce heat loss and increase energy efficiency—an especially important aspect in today’s world, where the focus on carbon emission reduction has intensified. Adherence to recognized standards also extends the service life of furnaces. Using high-quality materials, proper engineering design, and regular maintenance programs minimizes repair and replacement costs and prevents unplanned production downtime.

Key International Standards for Furnaces

Several key international standards must be observed in the design and construction of furnaces used in the oil and gas industry. These include API 560, ISO 13705, and ASME Section VIII, each with its specific applications and guidelines.

API 560

Developed by the American Petroleum Institute, API 560 is one of the most important standards for the design and construction of refinery furnaces. It outlines the requirements for structural design, material selection, combustion systems, and safety controls.

API 560 focuses on furnaces used for heating process fluids such as crude oil and other hydrocarbons. It addresses details such as proper tube spacing, burner type selection, and stack system design. The standard also provides solutions for reducing heat loss and outlines pre-commissioning inspection and testing requirements. Adhering to this standard is crucial in international projects that require alignment with global regulations and helps companies design and construct high-performance, safe furnaces.

ISO 13705

ISO 13705 is the international equivalent of API 560 and applies to furnaces used in the oil, gas, and petrochemical industries. This standard focuses on the design of fired heaters in refineries and covers requirements related to heat transfer, combustion, and safety.

It supports engineers in designing furnaces with high thermal efficiency and environmental compliance. ISO 13705 gives special attention to the selection of heat- and corrosion-resistant materials, as furnaces are continuously exposed to extreme thermal and chemical conditions. A key highlight of this standard is its emphasis on reducing greenhouse gas emissions and optimizing fuel consumption, in line with global sustainable development goals.

ASME Section VIII

The American Society of Mechanical Engineers (ASME) developed Section VIII of the Boiler and Pressure Vessel Code to govern the design and construction of pressure vessels and furnace components subject to high pressure, such as coils and fluid transfer tubes.

ASME Section VIII provides detailed requirements for material selection, non-destructive testing, and periodic inspection programs. Compliance with this standard helps prevent failures due to high pressure or material fatigue and ensures the safe design of components such as heat exchangers and radiant coils. Ultimately, following these guidelines reduces operational risks and increases confidence in continuous and safe furnace performance.

Types of Furnaces Used in the Oil and Gas Industry

Depending on the process type and operational needs, various furnace types are used in the oil and gas industry. Each has specific features and applications, and their design must comply with international standards.

Direct-Fired Furnaces

Direct-fired furnaces are among the most commonly used types in the industry, where heat is directly transferred from fuel combustion to the process fluid. They are used for heating crude oil, preheating distillation tower feeds, and cracking processes. The burners in these furnaces typically operate using natural gas or fuel oil.

Proper design of direct-fired furnaces ensures uniform heat transfer and prevents the formation of hot spots that could damage tubes. Strict adherence to API 560 is essential in designing these furnaces. One of the main challenges in using direct-fired furnaces is controlling pollutant emissions. Utilizing low-NOx burners and heat recovery systems can effectively reduce environmental impacts.

Convection Furnaces

Convection furnaces are another type used in the oil and gas industry, where heat transfer occurs primarily via hot gas flow. They are especially used in the convection section of refinery furnaces. The main advantage of these furnaces is their high efficiency in heat recovery: the hot combustion gases transfer their heat to the fluid inside the tubes before exiting through the stack. This reduces fuel consumption and operating costs.

The design of convection furnaces should prevent tube fouling and corrosion. ISO 13705 provides useful guidelines for material selection and design of these furnaces.

Electric Arc Furnaces

Electric arc furnaces are mainly used in specialized processes such as metal melting or the production of certain chemicals. These furnaces generate the required heat using electrical energy and are considered environmentally friendly due to the absence of fossil fuel usage. However, they involve high operational costs and require advanced electrical infrastructure.

In the oil and gas sector, electric arc furnaces are less common than fuel-based furnaces but are used in certain petrochemical processes requiring extremely high temperatures. Standards such as IEC 60519 govern the safe design and operation of these furnaces.

Also read: How to Choose the Right Industrial Furnace for Your Projects

Safety Requirements in Furnace Design and Operation

Safety is one of the most important aspects of furnace standards in the oil and gas industry. Due to the nature of furnace operations—high temperatures, flammable materials, and pressure—observing safety requirements is essential to prevent accidents.

Standards such as API 560 and ISO 13705 provide detailed guidelines for the design of emergency shutdown systems, installation of gas leak detectors, and proper ventilation systems. These systems must be designed to allow rapid shutdown in case of any malfunction or abnormal condition to prevent incident escalation.

Periodic inspections and non-destructive tests are vital for identifying cracks, corrosion, or structural weaknesses. ASME Section VIII offers recommendations in this area. Proper training of operators and technicians is also a critical safety requirement, enabling them to follow standard procedures and respond appropriately in emergencies.

Material Selection for Furnace Construction

Choosing the right materials for furnace construction is one of the most important decisions in the design process. Furnaces operate under extremely harsh conditions, including high temperatures, high pressures, and contact with corrosive chemicals. Therefore, materials must have high thermal and chemical resistance.

Common materials include heat-resistant alloy steels, refractory ceramics, and firebricks. API 560 and ISO 13705 provide precise guidelines for selecting these materials. One major challenge in this area is corrosion, which can be mitigated through the use of corrosion-resistant coatings and regular inspections.

Material selection must also consider the type of process fluid. For example, fluids with high acidity require materials with greater chemical resistance to prevent premature equipment failure.

Advanced Technologies in Furnace Design

Technological advancements have significantly improved furnace design and performance. Low-NOx burners, which reduce nitrogen oxide emissions by optimizing the fuel-to-air ratio, are one such innovation. These burners create cleaner combustion with lower environmental impact.

Additionally, advanced heat recovery systems that recirculate exhaust gas heat into the heating cycle have dramatically reduced fuel consumption. Smart control systems allow real-time monitoring and automatic adjustment of temperature, pressure, and fuel flow to prevent dangerous conditions.

Engineering simulation tools like HYSYS also assist engineers in optimizing furnace design and improving thermal efficiency. All of these modern technologies are developed in full alignment with standards like API 560.

Furnace Maintenance and Inspection

Regular maintenance and accurate inspections are essential to ensure furnace safety and efficiency. Periodic inspections help detect issues such as corrosion, cracks, or tube fouling, preventing unexpected failures. ASME Section VIII provides guidelines for non-destructive testing methods such as ultrasonic and radiographic tests.

Preventive maintenance includes timely replacement of worn parts, coil cleaning, and burner inspection, all of which help extend furnace life. Continuous training of maintenance operators and technicians to identify early signs of failure and implement corrective actions is another key element in successful maintenance programs.

Challenges and Optimization Solutions

One of the main challenges of furnaces in the oil and gas industry is high energy consumption. Optimized design and the use of heat recovery systems can significantly reduce this issue. ISO 13705 offers strategies for improving energy efficiency and reducing heat loss.

Emission control is another major challenge. The use of low-NOx burners and gas treatment systems can help mitigate environmental impacts. The complexity of refinery and petrochemical processes can make furnace design more difficult, but engineering simulation software and close collaboration among technical teams can help manage these challenges.

Conclusion

Furnace equipment standards in the oil and gas industry play a vital role in ensuring safety, efficiency, and long service life. Standards such as API 560, ISO 13705, and ASME Section VIII provide precise guidelines for the design, construction, operation, and maintenance of furnaces. Adherence to these standards reduces operational risks, optimizes costs, and minimizes environmental impacts.

Petrosazeh beinolmelal aram Co. with its team of experienced specialists and advanced equipment, is ready to provide design, construction, and maintenance services for refinery furnaces in accordance with international standards. For expert consultation, please contact us.

References

- American Petroleum Institute (API). (2020). API Standard 560: Fired Heaters for General Refinery Service.

- International Organization for Standardization (ISO). (2018). ISO 13705: Petroleum, Petrochemical and Natural Gas Industries – Fired Heaters for General Refinery Service.

- American Society of Mechanical Engineers (ASME). (2021). ASME Boiler and Pressure Vessel Code, Section VIII.

- National Fire Protection Association (NFPA). (2022). NFPA 86: Standard for Ovens and Furnaces.

- International Electrotechnical Commission (IEC). (2019). IEC 60519: Safety in Electroheating Installations.