In large industrial complexes such as refineries, energy efficiency plays a crucial role in reducing operational costs and improving product quality. One of the key pieces of equipment contributing to this goal is the heat exchanger. This device is responsible for transferring heat between two fluids without direct contact and is widely used in processes such as distillation, heat recovery, and stream cooling.

Petrosazeh Beinolmelal Aram (IPS), leveraging its engineering expertise and adherence to international standards, designs and manufactures heat exchangers that not only deliver high performance but also reduce energy consumption and extend equipment lifespan. The following sections examine the role of heat exchangers in process optimization and their importance in the refining industry.

Principled Heat Exchanger Design and Its Impact on Energy Efficiency

The design of heat exchangers in refineries is based on precise heat transfer calculations. Factors such as fluid type, operating pressure, inlet and outlet temperature, and tube material are carefully analyzed. Proper design minimizes heat loss and significantly enhances overall process efficiency.

Heat exchangers are designed according to international standards such as TEMA and ASME, which ensure high engineering accuracy and durability. These standards define parameters such as tube thickness, connection types, and pressure-temperature requirements. Adherence to these principles ultimately reduces equipment wear and fuel consumption in refinery heating units.

Types of Heat Exchangers Used in Refineries and Applications

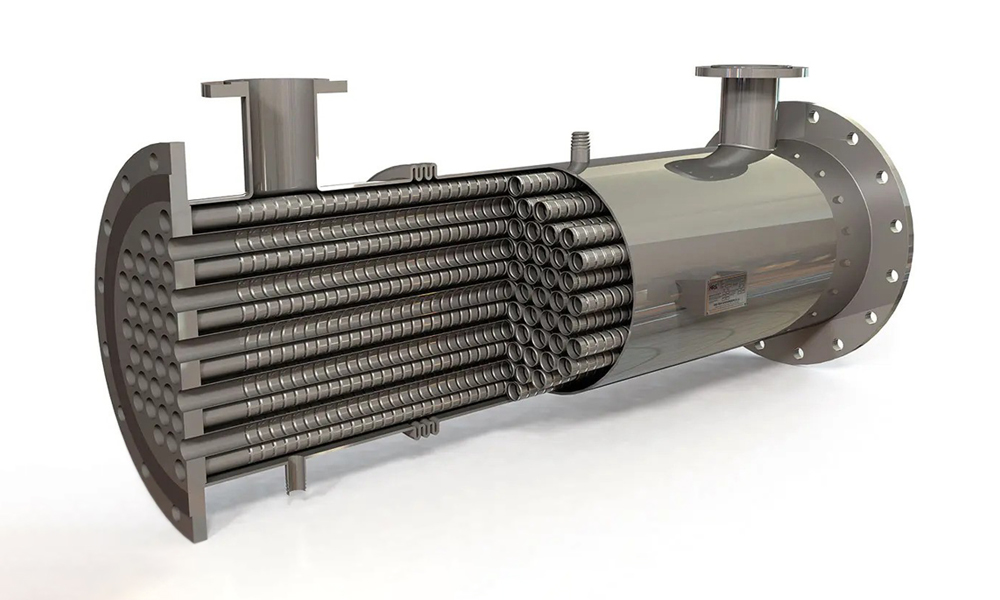

Various types of heat exchangers are used in refineries depending on process needs. The most common type is the shell and tube heat exchanger, capable of withstanding high pressure and temperature, typically used in crude oil distillation, heat recovery, and product cooling.

Plate heat exchangers are suitable for fast heat transfer in compact spaces, while tube to tube heat exchangers are cost-effective for small flow rates. Spiral heat exchangers are ideal for viscous fluids, and air-cooled exchangers are suitable for water-scarce regions.

Read more: Types of heat exchangers in refineries

The Role of Heat Exchangers in Reducing Fuel Consumption

In refinery processes, a large portion of energy is spent on heating or cooling fluids. By employing heat exchangers, the heat from hot streams can be transferred to cold streams, reducing the need for external fuel input. This technique, known as heat recovery, results in significant fuel savings and a reduction in environmental emissions.

In many projects designed by Petrosazeh, the use of high-efficiency heat exchangers has led to up to 30% energy savings. This improvement positively impacts not only operating costs but also the stability of process units.

Maintenance and Cleaning of Heat Exchangers

One of the major challenges in operating refinery heat exchangers is fouling or deposit formation inside tubes, which reduces heat transfer and efficiency. To prevent this, regular maintenance and effective filtration are essential.

Petrosazeh recommends performing scheduled chemical cleaning and periodic inspections. The use of corrosion-resistant coatings and anti-fouling alloys also plays a key role in extending exchanger lifespan.

International Standards for Refinery Heat Exchanger Design

Heat exchanger design is not limited to technical calculations; it must comply with global standards. The most important include:

- TEMA (Tubular Exchanger Manufacturers Association)

- ASME Section VIII

- API 660

- HEI Standards

These guidelines define procedures for pressure testing, thermal resistance, welding requirements, and operational safety. By adhering to these standards, Petrosazeh ensures the quality and safety of its heat exchangers, making them suitable for harsh refinery environments and ensuring longer service life.

The Importance of Material Selection in Heat Exchanger Performance

Selecting the right material for the tubes and shell directly affects performance and durability. Materials such as stainless steel, copper alloys, and titanium offer excellent resistance to corrosion and high temperatures.

At Petrosazeh, materials are chosen based on the specific process fluid and operating conditions to guarantee stable and long-term performance. Using high-quality materials also prevents leakage, unwanted pressure drops, and reduced heat transfer, ensuring consistent efficiency over years of operation.

Heat Exchangers and the Future of Energy Efficiency

With the advancement of modern technologies, heat exchanger design is evolving toward more compact, lightweight, and high-efficiency models. Petrosazeh is actively developing next-generation exchangers to meet the future demands of the oil and gas industry.

Enhancing energy efficiency in refineries not only contributes to economic savings but also helps reduce greenhouse gas emissions. Heat exchangers play a pivotal role in achieving this objective, making their proper design and maintenance essential for every industrial facility.

Read more: Installation and commissioning of heat exchangers in refineries

Conclusion

The heat exchanger is one of the most effective tools for energy management and thermal process optimization in refineries. Proper design, quality material selection, adherence to international standards, and regular maintenance are all critical factors that determine its performance and longevity.

Consistent maintenance ensures sustained heat efficiency and prevents premature wear. Ultimately, the proper use of heat exchangers not only leads to fuel savings but also supports environmental sustainability and energy stability across refinery operations.

References:

- https://heatxglobal.com/enhancing-heat-exchanger-efficiency-in-refineries-tackling-fouling-challenges-to-reduce-operational-costs/

- https://www.sciencedirect.com/science/article/pii/S2949821X25002066/

- https://industrialinsightnexus.substack.com/p/comprehensive-overview-of-heat-exchangers/

- https://www.ipieca.org/resources/energy-efficiency-compendium/heat-exchangers-2022/

- https://www.enerquip.com/oil-and-gas-industry-to-drive-heat-exchanger-market-in-coming-years/

- https://sensorex.com/heat-exchanger/

- https://www.mdpi.com/2227-9717/10/12/2541/

- https://petrostructure.com/en/blog/what-is-heat-exchanger/

- https://www.sinomechanical.com/news/Types-and-Primary-Functions-of-Heat-Exchangers-in-Refineries.html/

- https://www.tranter.com/industries-applications/refinery/

- https://sesinoks.com.tr/en/use-of-heat-exchangers-in-oil-refineries/