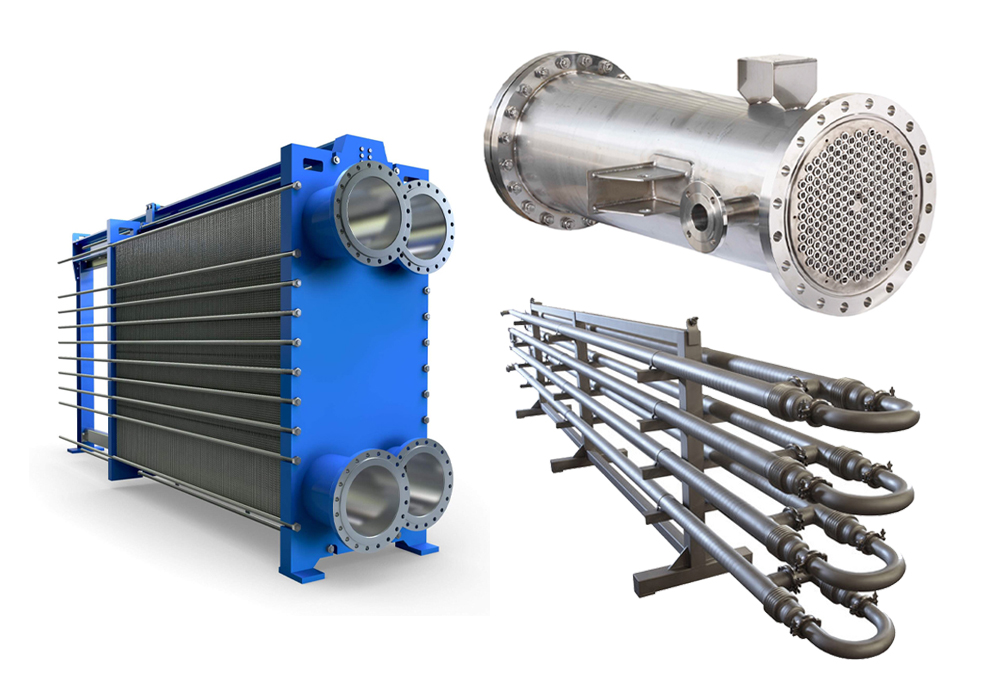

In many critical industries such as oil, gas, petrochemicals, refining, and power generation, heat exchangers are among the most vital process equipment. These devices play a key role in transferring heat between fluids at different temperatures, and their performance directly affects energy efficiency, system safety, and facility longevity.

In environments dealing with corrosive fluids (such as acids, alkalis, salt compounds, or highly corrosive chemical products), the design of heat exchangers becomes significantly more complex and sensitive. Incorrect material selection, improper design, or neglecting operational conditions can lead to rapid equipment degradation, increased maintenance costs, and even safety hazards.

Petrosazeh Beinolmelal Aram Co. (Petrosazeh), as a leading manufacturer of heat exchangers, designs specialized products for these challenging environments by adhering to global standards and utilizing advanced technologies. This article examines the key design principles for heat exchangers intended for corrosive environments.

Understanding Corrosive Environments and Design Challenges

Corrosive environments typically contain compounds that can react with metals and other materials. Such environments are commonly found in refinery units, petrochemical plants, water treatment facilities, and chemical production factories. Common characteristics of these environments include:

- Presence of strong acids and alkalis (e.g., HCl₄, H₂SO₄, NaOH)

- High temperatures and variable pressures

- Dissolved salts or corrosive gases like H₂S or chlorine

In such conditions, using standard heat exchangers without special design considerations can result in rapid corrosion, thermal cracking, fluid leakage, and eventually process shutdowns.

Selecting Corrosion-Resistant Materials

Suitable Construction Materials

The first and most critical step in designing heat exchangers for corrosive environments is selecting the right material. Based on operating conditions and fluid type, Petrosazeh uses materials with high resistance to corrosive factors, including:

- Stainless Steel 316L and 317L: Resistant to organic acids, saline solutions, and many chemical compounds.

- Nickel Alloys (Inconel, Hastelloy): Highly suitable for low pH and severely corrosive environments.

- Titanium: Excellent resistance against seawater and chloride solutions.

- Internal Polymeric or Ceramic Linings: To provide additional protection for fluid contact surfaces.

Quality Control Testing

Petrosazeh tests all materials for mechanical and chemical properties according to ASME Sec. VIII and TEMA Class R/C/B standards. This ensures that the produced heat exchangers not only exhibit chemical resistance but also achieve top-level thermal performance and physical strength.

Optimized Hydraulic and Thermal Design

In corrosive environments, material resistance alone is not sufficient; the fluid flow design and heat transfer configuration must also be engineered with precision.

Flow Arrangement and Internal Geometry

- Counterflow arrangements generally perform better than parallel flow in reducing thermal stresses and ensuring uniform heat distribution. Petrosazeh typically recommends this configuration for corrosive environments.

- Optimized baffle design directs fluid flow within the shell, preventing dead zones and fouling accumulation.

- Wherever possible, the corrosive fluid is routed through the tube side so that in case of leakage, hazardous materials are contained within the shell.

Use of Engineering Software

For hydraulic and thermal design, Petrosazeh uses software such as:

- HTRI Xchanger Suite

- Aspen Exchanger Design and Rating

- Ansys Fluent

These tools allow comprehensive simulation of designs before manufacturing.

Adherence to Industrial Standards

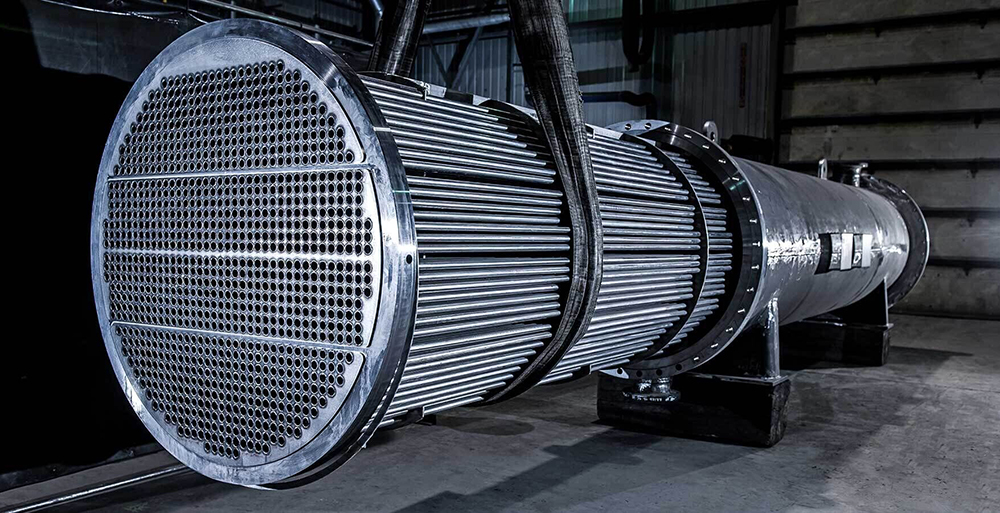

TEMA Standard

This standard specifically addresses the design and construction of shell and tube heat exchangers, covering aspects such as:

- Minimum baffle spacing

- Tube wall thickness under pressure

- Various tube configurations for corrosive conditions

ASME Sec. VIII

This standard pertains to the design and fabrication of pressure vessels, encompassing safety requirements, welding procedures, pressure testing, and quality control. Compliance with this standard is mandatory when designing heat exchangers for hazardous fluids.

Petrosazeh designs, tests, and certifies all its products in full compliance with these standards.

Economic Optimization in Design for Corrosive Environments

Balancing Cost and Performance

While corrosion-resistant materials usually incur higher initial costs, they economically justify the project by minimizing failures, extending service life, and reducing maintenance expenses over the long term.

Modular Design

Petrosazeh offers modular designs that allow:

- Partial replacement or upgrading of exchanger components (such as tube bundles)

- Reduced maintenance downtime

- Minimized capital expenditures for clients

Advanced Manufacturing and Coating Technologies

Industrial 3D Printing

Manufacturing components with complex geometries and high precision, especially in nozzles and intricate exchanger parts, has become possible through industrial 3D printers, a technology utilized by Petrosazeh.

Nano-Structured Coatings

- Enhanced resistance to fouling

- Reduction of localized corrosion

- Extended service life of internal components

These coatings are primarily applied to internal tubes or fluid-contact surfaces in corrosive environments.

Maintenance and Repair in Corrosive Environments

Preventive Maintenance

Petrosazeh recommends maintenance programs for corrosive environments that include:

- Periodic cleaning with suitable chemicals

- NDT inspections such as UT, PT, and RT

- Timely replacement of gaskets and packings

This proactive approach helps prevent early failures.

Design for Easy Access

Petrosazeh’s exchangers are designed for quick disassembly and access to internal components, reducing operational downtime and facilitating maintenance activities.

Environmental and Safety Considerations

Designing for corrosive environments necessitates heightened focus on safety and environmental protection. Petrosazeh addresses these concerns by:

- Leak-proof designs using standard flanges and welds

- Utilization of non-toxic and recyclable materials

- Designing energy-efficient exchangers to minimize greenhouse gas emissions

The Role of Simulation and AI in Optimized Design

In its recent projects, Petrosazeh Co has incorporated technologies such as:

- Genetic algorithms for exchanger dimension optimization

- CFD simulations to predict thermal behavior and stress distribution

- Field performance databases for machine learning-driven improvements

These technologies ensure the best possible designs for corrosive conditions.

Conclusion

Designing heat exchangers for corrosive environments requires a combination of technical expertise, understanding of operational conditions, intelligent material selection, leveraging advanced technologies, and strict adherence to international standards. Petrosazeh Beinolmelal Aram Co. (IPS), with its extensive experience and reliance on cutting-edge technologies, offers solutions that are not only technically advanced but also economically optimized.

By choosing corrosion-resistant equipment, precise design, and implementing preventive maintenance programs, system efficiency can be enhanced, costs reduced, and environmental health safeguarded.