Heat exchangers play a crucial role in optimizing processes and improving energy efficiency in refineries. These devices, with diverse designs and specific materials, can withstand various operational conditions. This article examines different types of heat exchanger, their construction materials, pressure and temperature ranges, and applications.

Shell and Tube Heat Exchanger

One of the most common types of heat exchangers consists of a cylindrical shell and a set of tubes. The construction materials typically include stainless steel, carbon steel, and nickel alloys. For corrosive fluids, materials such as titanium or Inconel are used. Shell and tube heat exchangers can usually withstand pressures up to 600 bar and temperatures up to 500°C. Their primary applications include crude oil refining, natural gas processing, chemical industries, and power plants.

Read more: Functioning of shell and tube heat exchangers

Also read: Guide to shell and tube heat exchangers design

Plate Heat Exchanger

Made from thin metal plates with materials such as stainless steel, titanium, or Hastelloy. The gaskets used in these exchangers are often made of EPDM or NBR, providing resistance to heat and corrosion. Plate heat exchanger can generally handle pressures up to 30 bar and temperatures up to 200°C, though gasket-free (welded) versions can withstand harsher conditions. Common applications include oil cooling, central heating systems, and food processing industries.

Spiral Plate Heat Exchanger

Consists of two metal plates coiled into a spiral shape. The construction materials include stainless steel or corrosion-resistant alloys. These exchangers can typically withstand pressures up to 25 bar and temperatures up to 300°C. Their advantages include resistance to fouling and ease of cleaning, making them suitable for viscous fluids or those containing suspended solid particles.

Plate and Frame Heat Exchanger

Made of corrugated metal plates with gaskets for sealing between them. These exchangers usually handle pressures up to 25 bar and temperatures up to 200°C. Their primary applications include heating and cooling processes in chemical, food, and pharmaceutical industries. Their modular structure and design flexibility are key features.

Also read: Plate vs. Shell-and-Tube heat exchanger thermal performance

Air Cooler Heat Exchanger

Uses air as the cooling medium. The tubes are typically made of carbon steel or stainless steel, while the fins are made of aluminum or copper. Air coolers can withstand pressures up to 100 bar and temperatures up to 400°C. They are particularly common in areas with limited water resources. Applications include petrochemical industries, refineries, and power plants.

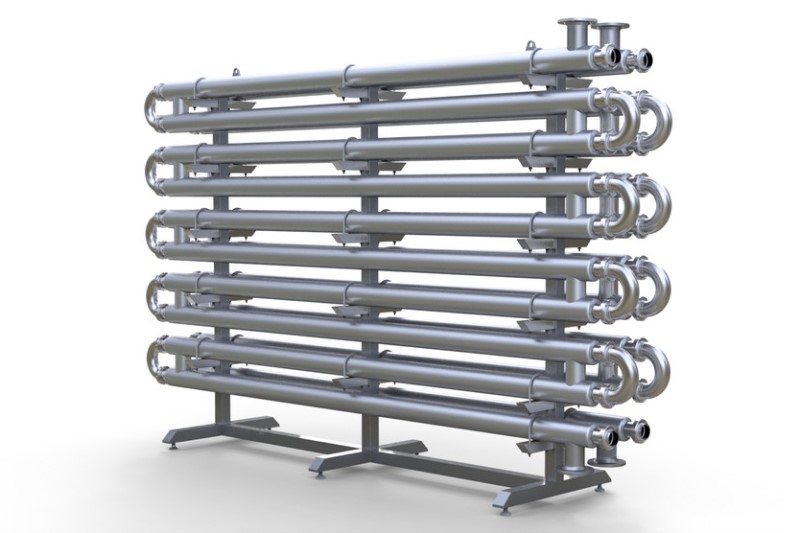

Double Pipe Heat Exchanger

Has a simple design consisting of two concentric pipes. Tube to tube heat exchangers are generally made of stainless steel or carbon steel and can handle pressures up to 150 bar and temperatures up to 400°C. They are mainly used in chemical industries for heating or cooling processes with low capacity.

Selecting the Right Heat Exchanger

Choosing the appropriate heat exchanger depends on several factors, including operational conditions, fluid types, maintenance costs, and available space. Petrosazeh international aram offers a wide range of high-quality heat exchangers tailored to different industrial needs. For more information, contact our specialists.

Role of Heat Exchangers in Enhancing Energy Efficiency in Refineries

Heat exchangers are among the most effective tools for heat recovery in refineries, reducing energy waste and improving thermal process efficiency. In refineries, hot outgoing fluids from processes can be used via heat exchangers to preheat incoming fluids instead of being discarded. This reduces fuel consumption and lowers greenhouse gas emissions.

Read more: The role of heat exchangers in fixed equipment

Comparison of The Efficiency of different Types of Heat Exchangers in Different Conditions

Using high-efficiency heat exchangers and optimized designs significantly contributes to energy savings. For instance, in distillation systems where significant heat is generated, plate or shell and tube exchangers can recover excess heat to preheat feedstock, reducing external heating needs and operational costs. Proper operation and maintenance planning can ensure their long-term efficiency.

Principles of Heat Exchanger Design in Refineries

Designing heat exchangers for refineries requires a deep understanding of heat transfer processes, fluid properties, and operational conditions. Selecting the type of exchanger, construction materials, dimensions, and flow arrangements must be carefully considered to achieve maximum efficiency. Specialized software like HTRI and Aspen HYSYS helps engineers design and simulate heat exchangers for optimal performance.

Comparing the Efficiency of Different Heat Exchangers Under Various Operating Conditions

The efficiency of heat exchangers depends on several factors, including exchanger type, construction materials, flow conditions, and temperature. For example, plate heat exchangers have higher efficiency in applications with low flow rates and small temperature differences, while shell and tube exchangers are more suitable for high-temperature and high-pressure conditions. Choosing the right exchanger according to operational requirements can significantly improve system efficiency.

Recent Innovations in Heat Exchanger Design for Refineries

With technological advancements, heat exchanger designs have evolved. The use of new materials with higher corrosion and temperature resistance, more compact and efficient designs, and advanced manufacturing techniques such as 3D printing have enabled the production of exchangers with higher efficiency and lower costs.

Impact of Material Selection on Heat Exchanger Lifespan

Choosing the right material for heat exchanger construction directly affects its lifespan and performance. Factors such as corrosion resistance, mechanical strength, weldability, and cost must be considered. For instance, using stainless steel in corrosive environments extends exchanger lifespan but is more expensive than carbon steel.

Optimizing Heat Exchanger Performance in Refineries

Optimizing heat exchanger performance can lead to energy savings and reduced operational costs. Methods such as improved design, advanced cleaning techniques, precise operational control, and continuous performance monitoring help achieve this goal.

Challenges Associated with Heat Exchangers in Complex Refinery Processes

In complex refinery processes, heat exchangers face challenges such as sudden temperature and pressure fluctuations, fluids with varying properties, and the need for operational flexibility. Proper design, high-quality material selection, and well-planned maintenance can help address these challenges.

Conclusion

Heat exchangers play a vital role in improving energy efficiency in refineries by recovering heat and reducing energy loss. Using high-efficiency exchangers, optimizing thermal processes, and proper operation can help lower fuel consumption and associated costs.

References:

• Heat Exchanger Design Handbook

• EngineeringToolBox.com