Heat exchangers are vital and integral components of industrial processes, especially in refineries. These devices are responsible for transferring heat between two or more fluids and directly affect efficiency, energy consumption, and even operational costs. Optimal performance of these exchangers can play a significant role in improving overall plant efficiency and reducing fuel consumption.

Petrosazeh Beinolmelal Aram Company (Petrosazeh), leveraging technical expertise, cutting-edge technology, and adherence to global standards, offers practical and advanced solutions to improve heat exchanger efficiency. This article provides a comprehensive overview of the most important methods for enhancing heat exchanger performance in industrial environments, particularly refineries.

Why is Increasing Heat Exchanger Efficiency Important?

In environments such as refineries, a large amount of energy is consumed for heating, cooling, and transferring heat between various fluids. Every percentage improvement in refinery heat exchanger efficiency can lead to significant energy savings, reduced fuel costs, and lower emissions of environmental pollutants.

As energy prices rise and industries shift towards greater efficiency, increasing the efficiency of heat exchangers becomes a necessity, not just an option. Additionally, reducing heat loss in the system enhances safety, extends equipment lifespan, and ensures production stability.

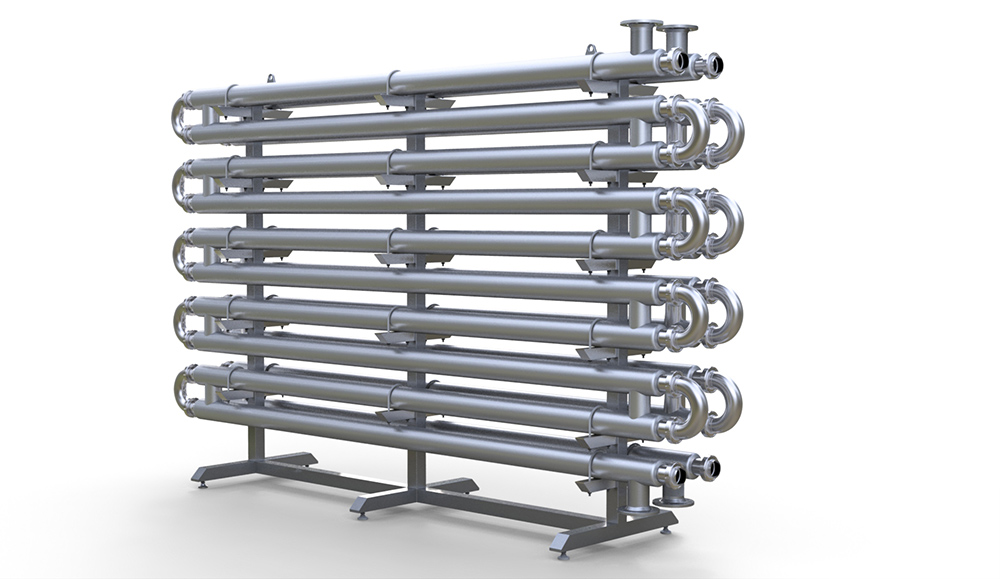

Proper Design and Structural Optimization of the Heat Exchanger

Design is one of the most critical factors determining the performance of a heat exchanger. The choice of flow type, material selection, geometric structure, and the arrangement of internal components such as baffles all impact final efficiency.

Counterflow vs. Parallel Flow: One of the most common strategies for improving efficiency is using a counterflow pattern. In this design, the hot and cold fluids move in opposite directions, creating the maximum possible temperature difference along the exchanger, thereby enhancing heat transfer.

Role of Baffles in Shell and Tube Heat Exchangers: In shell and tube heat exchangers, intelligent use of baffles to guide fluid flow and increase turbulence enhances the heat transfer coefficient. However, improper baffle design may result in excessive pressure drop; therefore, balancing high efficiency and low-pressure drop is crucial.

Use of Simulation Software: Nowadays, software like HTRI and Aspen Plus allows engineers to perform precise designs and evaluate exchanger performance before construction. Petrosazeh utilizes these tools to deliver exchangers with maximum efficiency to the market.

Utilization of Modern Technologies: Technological advancements have significantly impacted heat exchanger optimization. Innovations in materials, structures, and heat transfer fluids are among these developments.

Nanofluids: Using nanofluids (fluids containing nanoparticles with high thermal conductivity) is a modern method for increasing efficiency. These fluids transfer heat faster and more effectively than conventional fluids, showing impressive performance in high-temperature refinery processes.

Finned Tubes and Corrugated Plates: In shell and tube or plate heat exchangers, using finned tubes or plates with a corrugated structure increases the contact surface area between the fluid and the exchanger walls, thus accelerating heat exchange.

Anti-Corrosion and Anti-Fouling Coatings: A common problem in heat exchangers is the formation of deposits and internal surface corrosion, which drastically reduces efficiency. Utilizing special coatings resistant to corrosion and fouling not only extends the lifespan but also helps maintain efficiency in the long term. Petrosazeh employs these coatings in its products.

Fluid Flow Optimization in the Exchanger: The fluid flow pattern within the exchanger must be designed to maximize turbulence and achieve the highest heat transfer coefficient without causing excessive pressure drop.

Use of Inserts and Turbulence-Inducing Structures: Adding structures such as fins or small rings in the flow path can increase fluid turbulence. This enhances heat transfer from the surface to the fluid and vice versa.

Plate Heat Exchangers for Low Flow Rates: For situations with low fluid flow, plate heat exchangers are highly suitable due to their large contact surface area and compact design, which significantly boosts efficiency.

Preventive Maintenance and Regular Overhauls

Even the most advanced design and technology cannot maintain high efficiency without regular maintenance. Planning for cleaning, inspections, and replacing worn parts is a vital part of the efficiency enhancement strategy.

Regular Cleaning: Scaling caused by salts, chemicals, and suspended particles can gradually disrupt exchanger performance. Methods such as chemical washing or mechanical cleaning at scheduled intervals greatly help maintain performance.

Corrosion and Leak Monitoring: Regular inspection of equipment to detect leaks, surface cracks, or internal corrosion prevents serious future damages. Petrosazeh provides specialized after-sales services in this field to ensure customers’ heat exchangers remain in optimal condition.

Managing Fouling and Corrosion: Deposits can block flow paths, reduce heat exchange, and increase energy consumption. To combat them, preventive methods must be employed:

- Selecting corrosion-resistant materials (such as stainless steel)

- Installing pre-filters to remove suspended particles

- Using fluid quality control systems

- Applying modern technologies like ultrasonic waves to remove deposits during operation

Utilizing Intelligent Control Systems

Digital and automated control systems can continuously monitor the temperature, pressure, flow, and overall performance conditions of the exchanger. These systems can provide early warnings and allow corrective actions before serious problems arise.

Using SCADA systems or Programmable Logic Controllers (PLC) ensures continuous performance optimization. Petrosazeh incorporates these technologies in its latest designs.

Energy Consumption Management: Heat exchangers are at the heart of many energy-consuming processes. Therefore, increasing their efficiency directly impacts fuel consumption reduction and overall system efficiency.

Energy Recovery: Residual heat in exhaust gases or used fluids can be recovered using properly designed heat exchangers. This energy can be reintegrated into the process, thereby reducing costs.

Use of Multi-Stage Systems: Multi-stage exchangers (Cascade Systems) enable heat transfer to occur in multiple phases, maximizing the utilization of available energy.

Read more: Installation and commissioning of heat exchangers in refineries

Correct Selection of Exchanger Type

Tube, plate, air-cooled, and other types of exchangers are each designed for specific conditions. Incorrect selection can lead to low efficiency and heavy maintenance costs.

- For high temperature and pressure: shell and tube exchangers are suitable.

- For limited spaces or corrosive fluids: plate exchangers are a good choice.

- For portable or temporary applications: tube to tube heat exchangers are more appropriate.

Also read: Types of heat exchangers in refineries

Training and Personnel Awareness

End users, i.e., operators and maintenance teams, play a crucial role in maintaining efficiency. Proper training on operation, maintenance, and problem identification is an important part of the performance optimization strategy. Petrosazeh assists its clients by offering training courses, technical documentation, and consultancy services.

Conclusion

Improving the efficiency of heat exchangers in refineries requires a multi-faceted approach: from optimal design to intelligent maintenance and the adoption of modern technologies. Petrosazeh International Aram (IPS), with its technical expertise and field experience, provides comprehensive solutions to enhance the performance of these critical devices.

Investing in the efficiency improvement of heat exchangers not only reduces energy consumption and operational costs but also guarantees system safety, longevity, and sustainability.