Storage tanks play a crucial role in resource management across various industries, particularly in the oil and gas sector. However, one of the major challenges in this field is the evaporation of fluids and its environmental consequences. The volatility of certain fluids such as gasoline, crude oil, and other hydrocarbons allows their vapors to easily enter the atmosphere, leading not only to financial losses but also to air pollution and increased safety hazards such as fire risks. Floating roof tanks have been designed as an effective engineering solution to address these challenges.

These tanks feature a roof that floats directly on the liquid surface and moves up or down in response to changes in liquid volume. This design eliminates or minimizes the vapor space above the

fluid, thereby significantly reducing evaporation. Consequently, this technology not only prevents the loss of valuable materials but also effectively curtails the release of environmental pollutants.

Floating roof tanks are widely used in refineries, petrochemical facilities, and industries involved in the storage of both light and heavy hydrocarbons due to their high efficiency and economic and environmental benefits. This paper provides a comprehensive review of the structure, functionality, advantages, and challenges of these tanks from a technical perspective.

Structure and Functionality of Floating Roof Tanks

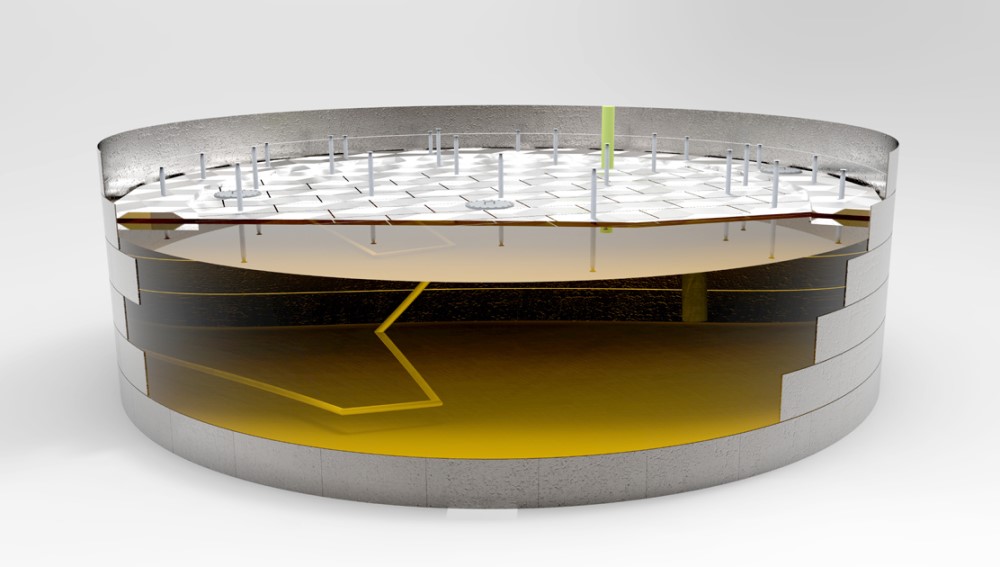

Floating roof tanks are typically cylindrical, with the roof attached to the tank walls using specialized sealing systems. The roof material is usually selected from steel, aluminum, or composite materials to ensure both corrosion resistance and lightweight properties.

The operational mechanism of these tanks is simple yet highly effective. In Fixed roof tanks, an empty vapor space above the liquid surface allows volatile vapors to accumulate. In contrast, floating roof tanks eliminate this vapor space by placing the roof directly on the liquid surface, reducing evaporation. The sealing system at the interface between the roof and the tank wall prevents vapor leaks and keeps the fluid isolated from atmospheric oxygen.

This design reduces the evaporation of volatile substances by up to 90% and minimizes the emission of volatile organic compounds (VOCs), which are primary contributors to air pollution. As a result, floating roof tanks not only prevent economic losses due to fluid evaporation but also mitigate adverse environmental and health impacts.

Types of Floating Roof Tanks and Their Differences

Floating roof tanks are categorized into two main types: External Floating Roof Tanks (EFRT) and Internal Floating Roof Tanks (IFRT). Each type has distinct characteristics, making them suitable for different storage conditions based on the fluid type, climate, and environmental regulations.

External Floating Roof Tanks (EFRT): These tanks have roofs that are exposed to open air. Due to their simpler design, they have lower construction and maintenance costs and are commonly used for fluids with moderate evaporation rates, such as certain oils and chemicals. However, since the roof is exposed to rain, snow, dust, and other environmental factors, contaminants may infiltrate the stored fluid.

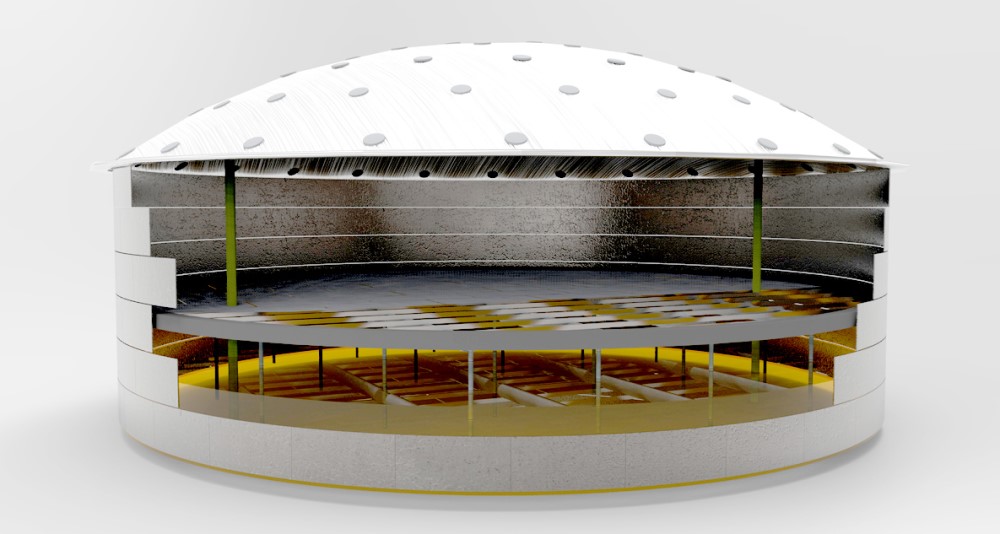

Internal Floating Roof Tanks (IFRT): These tanks feature an additional fixed roof that protects the floating roof from environmental elements. This design maximizes evaporation control and prevents dust, moisture, and other contaminants from entering the tank. IFRTs are typically used for storing high-vapor-pressure fluids such as gasoline, jet fuel, and certain sensitive chemicals, as they enhance safety while reducing evaporation by up to 90%.

The choice between these two types depends on the fluid properties, environmental conditions, safety requirements, and project budget. While internal floating roof tanks offer superior evaporation control, their initial costs are higher than external floating roof tanks.

Environmental and Economic Benefits of Floating Roof Tanks

One of the most significant advantages of floating roof tanks is their role in reducing air pollution and preserving the environment. In refineries and petrochemical industries, hydrocarbon vapor emissions contribute to air pollution, photochemical smog formation, and increased greenhouse gases. The use of floating roof tanks reduces VOC emissions, thereby significantly improving air quality.

From an economic perspective, reduced evaporation translates to decreased loss of valuable materials. In large refineries, even minor evaporation losses over time can result in substantial financial setbacks. Floating roof tanks minimize such losses, thus improving operational costs.

Additionally, these tanks lower the risks of fire and explosion since reduced evaporation leads to fewer flammable vapors. This not only enhances the safety of personnel and industrial facilities but also reduces insurance costs and safety expenditures.

Challenges and Limitations of Floating Roof Tanks

Despite their numerous advantages, floating roof tanks also present some challenges and limitations. One major issue is their sensitivity to weather conditions. In external floating roof tanks, rain, snow, and dust can accumulate on the roof, potentially affecting its functionality if not properly managed.

Another challenge is the need for regular maintenance of the sealing system. If the seal does not function correctly, vapor leakage may increase, compromising the tank’s efficiency. This is particularly concerning when storing corrosive fluids, as it may elevate maintenance costs.

Furthermore, these tanks may not be ideal for fluids with extremely high vapor Pressure vessels or for large-scale storage operations. In such cases, pressurized or fixed-roof tanks may be more suitable alternatives.

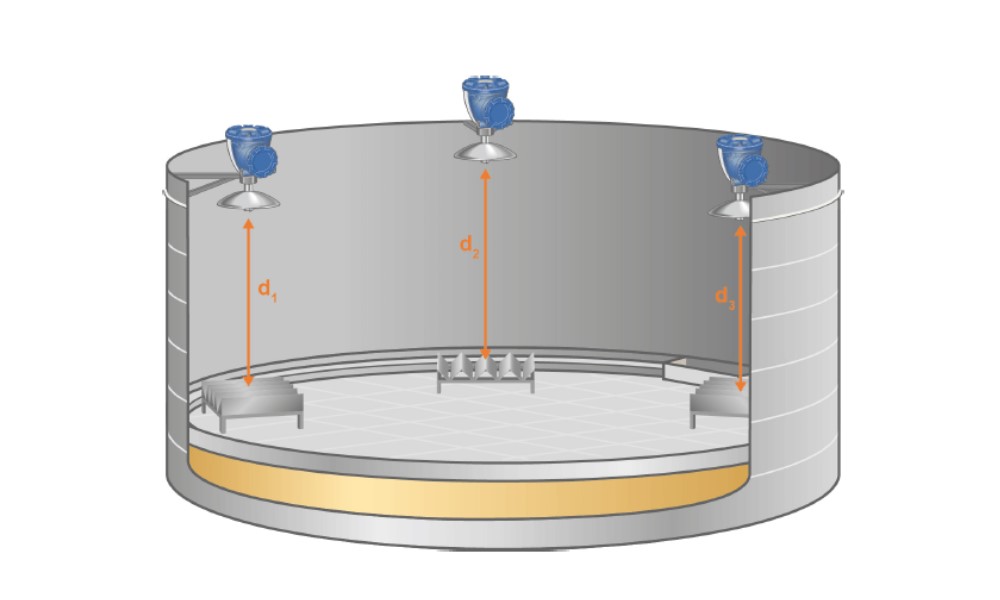

Nevertheless, most of these challenges can be managed through appropriate engineering designs and routine maintenance. The future of this technology lies in the use of advanced materials, smart monitoring systems, and optimized designs to enhance energy efficiency and environmental sustainability.

Design and Construction of Floating Roof Tanks

The design of floating roof tanks requires high engineering precision to maximize efficiency while meeting safety standards. One of the key design factors is selecting appropriate materials. Floating roofs are typically made from aluminum or stainless steel due to their lightweight properties and high resistance to corrosion and harsh environmental conditions. The tank body must also withstand internal and external pressures, particularly in areas prone to temperature fluctuations or seismic activity.

A critical component of these tanks is the sealing system, which must prevent vapor leaks while accommodating roof movement. Some designs use flexible rubber, specialized foams, or advanced polymer composites for sealing, with material selection based on stored fluid type, environmental conditions, and regulatory standards.

Tank dimensions and shape depend on storage requirements. For larger tanks, telescopic supports may be used on the roof to prevent contact with the tank bottom when fluid levels decrease. In earthquake-prone regions, additional reinforcements must be incorporated to mitigate seismic risks.

Floating roof tanks are constructed following international standards such as API 650, which specifies requirements for design, welding, sealing, and safety testing to ensure reliable operation under diverse conditions.

Also read: How are floating roof tanks constructed?

Maintenance and Optimization of Floating Roof Tanks

Proper maintenance is essential for maximizing the lifespan and efficiency of floating roof tanks. One of the most critical tasks is periodic inspection of the sealing system, as any wear, cracks, or tears can lead to increased evaporation and vapor leakage. Regular cleaning also prevents debris accumulation, which may hinder roof movement.

In cold climates, one of the main concerns is freezing on the tank roof and sealing system. To prevent this, drainage systems can be installed on external roofs to remove rainwater or snow accumulation. Additionally, anti-corrosion coatings and temperature-resistant paints can extend the tank’s service life.

To optimize floating roof tank performance, advanced technologies such as level and pressure sensors can be implemented. These sensors enable real-time monitoring of liquid levels, internal pressure, and sealing conditions, allowing operators to take corrective actions promptly. In some cases, adding thermal insulation layers on the roof can further reduce environmental heat transfer and evaporation.

These measures enhance tank efficiency while reducing long-term operational and maintenance costs. Preventive maintenance is key to ensuring the durability and functionality of these tanks.

Innovations in Floating Roof Tank Technology

Advancements in technology have led to improvements in floating roof tank efficiency. One notable innovation is the use of advanced composite materials for roof construction. These materials not only reduce tank weight but also provide superior corrosion resistance and durability.

Another major development is the integration of smart monitoring systems and the Internet of Things (IoT). Smart sensors can transmit real-time data on liquid levels, vapor pressure, and sealing conditions, enabling facility managers to optimize maintenance strategies.

Additionally, researchers are exploring nanofluids that enhance thermal conductivity, potentially improving heat transfer control and minimizing evaporation. New dual-layer roof designs further reduce environmental heat transfer, increasing tank efficiency.

These innovations suggest that floating roof tanks will continue to evolve, meeting the growing demands of industries while enhancing environmental sustainability and energy efficiency.

Read more:

Difference between fixed roof and floating roof cylindrical tanks

Types of tank roofs: A comprehensive guide

Resources:

- EPA: “Understanding Floating Roof Tanks and Emissions Control”

- Engineering Toolbox: “Floating Roof Tank Design and Applications”

- ScienceDirect: “Reduction of Evaporation Losses in Storage Tanks”

- Oil & Gas Journal: “Floating Roof Tanks: Design and Environmental Benefits”

- API Standards: “API 650 – Welded Tanks for Oil Storage”