Refinery furnaces are a core component in the process of converting crude oil into valuable products, and selecting the right materials for tubes and walls has a direct impact on operational safety, durability, and efficiency. In environments characterized by high temperatures, extreme pressures, and corrosive conditions, materials must withstand heat exceeding 1000°C, mechanical stresses, and chemical attacks to ensure stable furnace performance.

This article aims to provide practical information to professionals and enthusiasts in refinery technologies, examining challenges, technical solutions, and practical considerations in selecting furnace materials, enabling more precise decision-making for industrial projects.

Choosing appropriate materials increases the furnace’s service life, reduces unplanned downtime, and minimizes potential workplace hazards. For instance, furnace shutdowns caused by tube corrosion not only incur financial costs but also pose safety risks to personnel. Petrosazeh Company applies API 560 and ASME standards to select materials tailored to each refinery’s operating conditions and process type, ensuring a balance of durability, safety, and energy efficiency. This article covers all aspects of material selection for industrial furnaces, from technical analysis to real-world experience, offering a comprehensive and practical guide.

Understanding Refinery Furnaces and Their Main Components

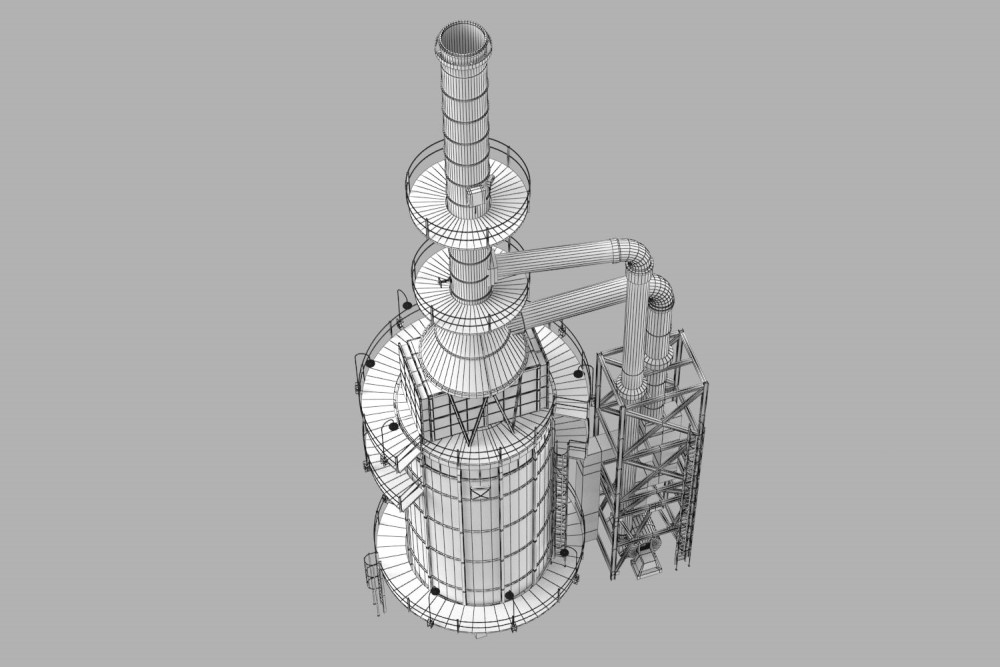

Refinery furnaces, often referred to as direct-fired heaters, are designed to heat process fluids such as crude oil or gases to high temperatures. These furnaces typically comprise three main sections:

- Radiant section: Contains the tubes and transfers heat directly from the flame to the process fluid.

- Convection section: Facilitates heat transfer via the flow of hot gases.

- Insulating walls: Preserve internal heat and prevent energy losses.

Tubes, generally made from heat-resistant metal alloys, transport process fluids and must withstand direct flame exposure and high thermal stresses. Walls, which may consist of brick layers or castable refractory materials, must prevent heat penetration while resisting wear and thermal shock.

Importance of Selecting Suitable Materials for Industrial Furnaces

Choosing the right material extends the lifespan of refinery furnaces, reduces energy consumption, and enhances safety. In refineries, where temperatures may reach 1200°C, improper materials can lead to carburization, oxidation, or even structural failure. Material selection must be based on a detailed analysis of operating conditions, including fuel type, internal pressure, and chemical composition of the fluids.

Petrosazeh emphasizes that initial investment in high-quality materials lowers long-term costs. For example, using creep-resistant alloys in tubes can extend maintenance intervals from five to ten years. Beyond economic benefits, this approach aligns with environmental standards, as reduced leaks and downtime decrease pollutant emissions.

The importance of proper material selection has led many refineries to use simulation software to predict material behavior. This proactive approach manages operational risks and allows operators to focus on production rather than repairs.

Also read: Energy Optimization in Industrial Furnaces

Common Materials for Refinery Furnace Tubes

Furnace tubes are often manufactured from high-temperature resistant steel alloys such as 5Cr-1Mo or 9Cr-1Mo, offering excellent oxidation and creep resistance. These materials are suitable for environments exceeding 600°C and are widely used in cracking furnaces and reformers. Nickel-chromium alloys such as Incoloy H800 or HP-Nb are also popular due to their resistance to sulfide attack and extended service life.

Key factors in selecting these materials include chromium and molybdenum content. For instance, 25Cr–35Ni alloys with niobium additions exhibit high thermal strength and are commonly used in radiant tubes.

Superalloys like Inconel 617 are ideal for temperatures above 1000°C, where creep and oxidation are major challenges. Although more expensive, these materials perform excellently in ethylene cracking furnaces and are compatible with hydrogen-rich environments. Final selection should be based on cost-benefit analysis, yet global experience shows that investing in these alloys is worthwhile.

Suitable Materials for Refinery Furnace Walls

Furnace walls must not only provide effective thermal insulation but also resist thermal shock, abrasion, and corrosive gases. In refineries, low-cement castable refractories are widely used due to ease of installation and longer service life. For chemically aggressive environments, magnesium-chrome compounds or zirconia-based refractories are recommended due to their excellent resistance to chemical reactions.

Factors Affecting Material Selection for Furnace Equipment

- Operating temperature: Materials must have an appropriate coefficient of thermal expansion to prevent cracking. In industrial furnaces with variable temperatures, creep-resistant alloys are preferred.

- Chemical composition of fluids: Elements like sulfur or hydrogen can accelerate corrosion, so materials with high chromium content are selected.

- Operating pressure: Tubes must withstand high pressures without excessive thickness.

- Cost vs. service life: More expensive materials can reduce long-term maintenance costs. Petrosazeh considers both initial cost and expected service life to balance quality and budget.Standards such as API 936 and ASME define material quality criteria to prevent premature failure.

Common Challenges and Practical Solutions in Furnace Materials

In refinery environments, challenges include sulfide corrosion, thermal shock, creep, and hydrogen attack. Effective solutions include:

- Using aluminized or nickel coatings to prevent oxidation.

- Selecting molybdenum-containing alloys for hydrogen resistance.

- Employing flexible castable refractories to prevent wall cracking.

- Installing smart monitoring sensors for real-time temperature control and early damage detection.

Innovations in Materials and Technologies for Industrial Furnaces

Recently, refractory nanocomposites and plasma-sprayed coatings have emerged as innovative solutions, reducing furnace weight while increasing abrasion and thermal resistance. Chrome-free refractories are also gaining popularity as environmentally friendly alternatives.

Practical Recommendations by Petrosazeh for Material Selection

Petrosazeh recommends initiating material selection with a detailed analysis of site conditions, including fluid corrosion testing. For tubes, Cr-Mo alloys are suggested for medium temperatures, and for walls, low-density castable refractories are recommended. Collaboration with experts for thermal and mechanical simulations is essential for design.

In the process of equipping a refinery furnace, regular maintenance, such as ultrasonic inspections, is crucial to detect and address potential issues early. Project budgets should focus on materials with high return on investment, as combining traditional materials with modern technologies yields optimal durability, safety, and economic efficiency.

Conclusion

Selecting suitable materials for refinery furnace tubes and walls is key to operational success. By understanding critical factors and innovations, challenges can be effectively managed. Ultimately, investing in proper materials ensures safety and supports industrial growth.

Reference:

- https://www.neonickel.com/technical-resources/which-materials-are-the-best-for-a-heat-exchanger-application/

- https://refractorychauhangroup.com/Petrochemical-Industry.html/

- https://www.digitalrefining.com/article/1000766/key-factors-in-selecting-refractories-for-the-hydrocarbon-processing-industry/

- https://www.jucosrefractory.com/info/how-to-choose-lining-structure-for-tubular-hea-97206315.html/

- https://www.morganthermalceramics.com/media/4i3luyxm/advanced-thermal-management-solutions-for-petrochemical-and-refinery-processes.pdf/

- https://inspectioneering.com/journal/2014-02-19/3785/managing-fired-furnace-tubes-i/

- https://nickelinstitute.org/media/8daa620a52ec647/10071_wroughtandcastheatresistantstainlesssteelsnickelalloysrefiningpetrochemical.pdf/

- https://becht.com/becht-blog/entry/introduction-to-refractory/

- https://www1.eere.energy.gov/manufacturing/industries_technologies/imf/pdfs/refractoriesreportfinal.pdf/

- https://www.pdhonline.com/courses/m158/m158content.pdf/

- https://rai-1.com/refractory-components-in-the-oil-and-gas-industry/

- https://www.jucosrefractory.com/info/how-to-choose-the-refractory-materials-for-the-102291777.html/

- https://americanstainlessandsupply.com/resources/project-manager-guide-alloy-steel-material-properties/

- https://industrialmetalservice.com/metal-university/the-best-metal-for-high-heat-applications/?srsltid=AfmBOopINkuZWq8mCopD-wh4rpoo8NlH-X-k_xAdeMYW4vSTwHsYw0bh/

- https://www.solitaire-overseas.com/blog/a-complete-guide-to-alloy-steel-pipes-its-uses-and-specifications/

- https://songshunsteel.com/inconel-718-steel-tubes-high-temperature-resistance-application-scenarios/

- https://www.enerquip.com/heat-exchanger-material-selection/

- https://www.scribd.com/presentation/513086605/Material-Selection-for-Refinery-Application/

- https://integratedglobal.com/en/5-common-causes-of-refractory-failure-and-how-to-fix-them/

- https://preconsfurnaces.com/how-do-furnaces-enhance-production-processes/