Shell and tube heat exchangers are among the critical equipment in refineries, responsible for transferring heat between fluids with different temperatures. With their unique structure, these exchangers enable efficient and safe heat exchange. This article provides a comprehensive analysis of the design and selection of shell and tube heat exchangers for refineries.

What is a Shell and Tube Heat Exchanger?

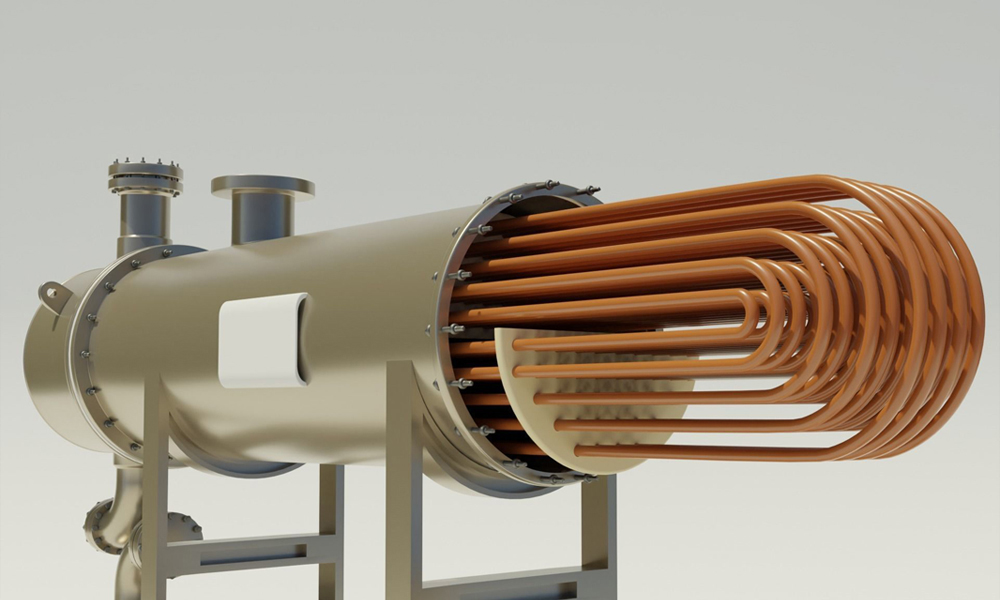

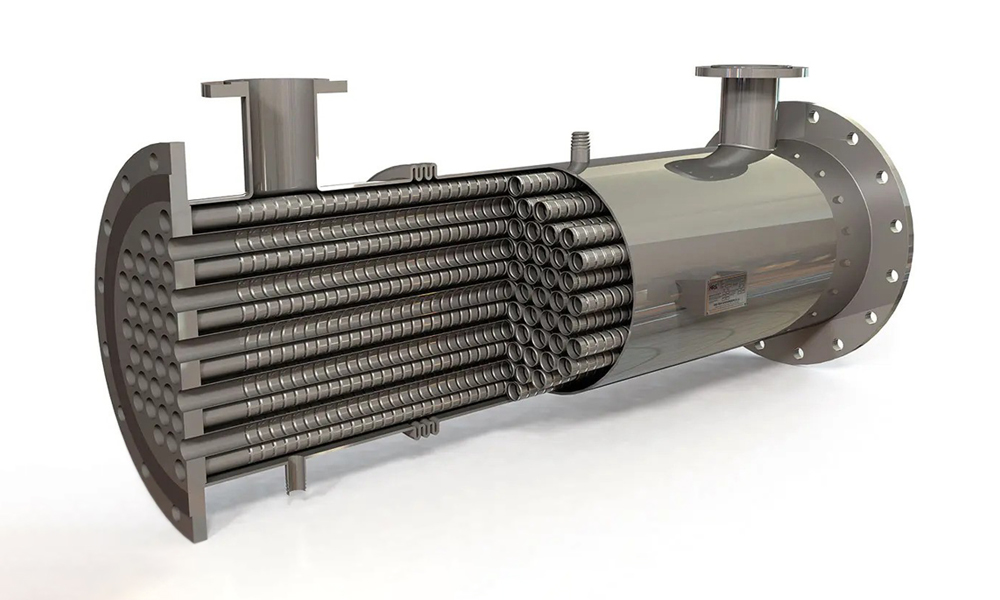

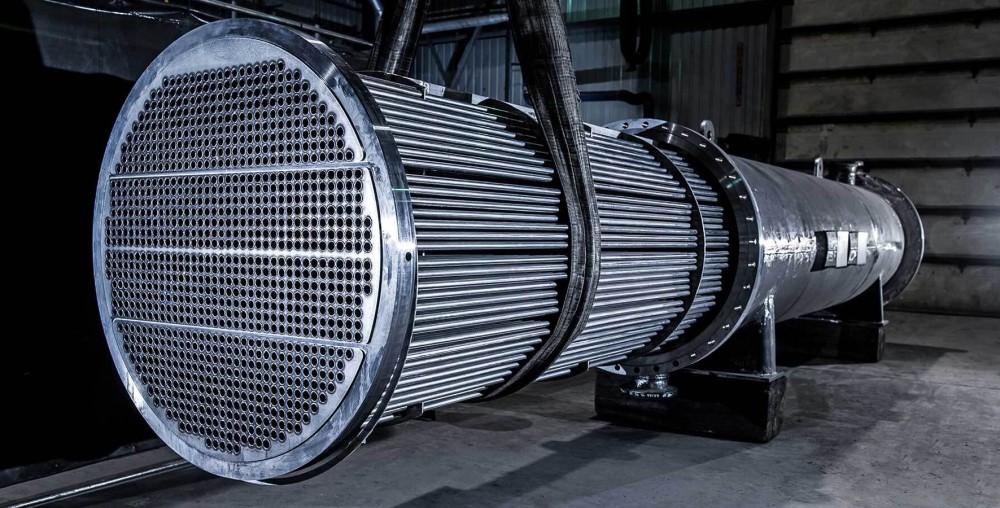

Shell and tube heat exchangers are devices where one fluid flows through tubes while another fluid flows around the tubes (inside the shell). This structure allows heat transfer between the two fluids without direct contact. In refineries, these exchangers are used in various processes such as distillation, cooling, and fluid heating.

Main Components of Shell and Tube Heat Exchangers

The structure of shell and tube heat exchangers includes the following components:

- Shell: A cylindrical casing containing the tubes where the shell-side fluid flows.

- Tubes: The passages through which the fluids flow and transfer heat.

- Tube Sheets: End plates to which the tubes are attached, preventing fluid leakage.

- Baffles: Internal plates that direct fluid flow within the shell and enhance heat transfer.

Principles of Designing Shell and Tube Heat Exchangers

Designing shell and tube heat exchangers is a complex process requiring careful consideration of various parameters. These parameters include fluid properties, operating temperature and pressure, heat transfer rate, materials used, and environmental conditions. The design principles should ensure not only process efficiency but also optimal energy utilization and high performance.

In this section, we will examine the principles of designing shell and tube heat exchangers and the factors to consider in their design. By understanding these principles, it is possible to design and implement exchangers with high efficiency, long service life, and low operational costs.

Material Selection

Selecting appropriate materials for shell and tube heat exchangers is crucial. These materials must have specific properties to withstand harsh operating conditions such as high temperatures, high pressures, and exposure to corrosive and toxic fluids. The key factors in material selection include:

Corrosion Resistance

In refineries, various fluids such as water, acidic gases, crude oil, and other chemicals can cause corrosion and damage the exchanger’s internal surfaces. Therefore, the chosen materials must have high corrosion resistance. Stainless steel is widely used due to its high corrosion resistance. In some specific conditions, special alloys like titanium and nickel are also used.

Wear Resistance

In heat exchanger where fluids contain suspended particles (such as dusty gases or liquids with fine particles), materials must have high wear resistance. Wear-resistant alloys such as chromium or molybdenum can be used for this purpose.

Compatibility with Fluids

Many refinery fluids, such as crude oil, natural gas, and corrosive chemicals, require specific materials to prevent unwanted chemical reactions. The materials should be compatible with these fluids to prevent issues like corrosion and scaling.

Determining Dimensions

Choosing appropriate dimensions for shell and tube heat exchangers is a crucial factor in optimal design. The exchanger’s dimensions should be selected to fully meet the thermal requirements of the process while avoiding excessive costs and space usage. Important considerations include:

- Tube Length and Diameter: Tube length depends on heat transfer requirements and physical limitations in the refinery. Generally, to ensure high heat transfer, the number and length of tubes should be designed so that the desired fluid temperature is maintained along the path. Tube diameter should be selected to facilitate fluid flow while minimizing pressure drop.

- Shell Width: Shell dimensions should be chosen to allow fluid flow with minimal resistance. If a direct fluid flow inside the shell is required, properly designed baffles should be used to optimize flow and reduce heat loss.

- Heat Transfer Capacity: The exchanger’s dimensions should be chosen to meet the required heat transfer capacity for the process. This parameter depends on fluid flow rates, temperatures, and thermal properties.

Tube Selection and Arrangement

The number and type of tubes are critical aspects of heat exchanger design and must be carefully determined based on parameters such as fluid flow rate, velocity, properties, and heat transfer type:

- Number of Tubes: The number of tubes directly affects fluid flow rate and heat transfer. To meet the thermal requirements of a specific process, the tube count should be sufficient to achieve the required heat exchange. For high fluid flow rates, more tubes should be used to reduce pressure drop.

- Tube Material: Tubes can be made from various materials such as steel, copper, titanium, or special alloys. The tube material should be selected based on the fluid type and operating conditions. For corrosive or high-temperature fluids, heat-resistant and corrosion-resistant tubes are preferred.

- Tube Arrangement: The tube layout (e.g., single-pass or multi-pass) influences exchanger performance. In multi-pass exchangers, the fluid flows multiple times through the tubes, increasing contact time and improving heat transfer efficiency.

Baffle Design

Baffles play a crucial role in enhancing heat transfer and controlling fluid flow in shell and tube heat exchangers. Proper baffle design significantly impacts exchanger performance:

- Baffle Function: Baffles direct the shell-side fluid flow. Without baffles, the fluid may flow randomly, reducing heat transfer efficiency. Properly designed baffles ensure uniform and directed flow.

- Preventing Dead Zones: Dead zones occur when fluid remains stagnant in certain areas of the shell due to poor design, leading to inefficient heat transfer. Proper baffle placement prevents these dead zones and enhances exchanger efficiency.

- Baffle Design Parameters: Baffles should be designed to minimize pressure drop while optimizing heat transfer. The spacing between baffles, their shape (straight or helical), and their placement in the shell are all critical factors in effective heat exchanger design.

Selecting Shell and Tube Heat Exchangers for Refineries

When selecting heat exchangers for refineries, the following factors should be considered:

- Thermal Capacity: The exchanger must meet the process’s thermal requirements.

- Resistance to Pressure and Temperature: It should withstand the refinery’s harsh operating conditions.

- Ease of Maintenance: The design should allow for easy maintenance and cleaning.

- Cost: Construction and maintenance costs should align with the refinery’s budget.

Challenges and Solutions in Designing and Selecting

Shell and Tube Heat Exchangers Designing and selecting heat exchangers come with challenges such as material selection, cost management, and performance optimization. Utilizing simulation software and consulting experts can help overcome these challenges effectively.

Conclusion

Shell and tube heat exchangers are essential equipment in refineries, facilitating heat transfer between fluids of different temperatures in processes such as distillation, cooling, and fluid heating. Proper selection and optimal design of these exchangers significantly impact energy efficiency and operational cost reduction.

Given the complexity of refinery processes and specific conditions, heat exchanger design should be carried out meticulously. Factors such as temperature, pressure, fluid type, and costs must be considered to ensure optimal performance and equipment safety. Additionally, regular maintenance and periodic cleaning are crucial to prevent efficiency loss and potential damage.

Ultimately, selecting the right heat exchangers helps refineries operate more efficiently and utilize energy resources effectively. Adhering to international standards, consulting experts, and using simulation software can aid in designing and selecting heat exchangers while minimizing challenges. Petrostructure Company, with a team of experienced and specialized experts in the field of heat exchanger design and consulting, is ready to help you select and design the most suitable equipment. For further advice and more detailed information, contact our experts.

References

- TEMA (Tubular Exchanger Manufacturers Association)

- ASME (American Society of Mechanical Engineers)