Heat exchangers are key components in various industries such as oil and gas, petrochemicals, HVAC, and food processing. Their primary function is to transfer heat between two or more fluids. Among the different types of heat exchangers, plate heat exchangers and shell-and-tube heat exchangers are the most commonly used. Each has its own characteristics, advantages, and limitations, making them suitable for different applications. This article explores the thermal performance differences between these two types of heat exchangers, analyzing their design aspects, efficiency, applications, and performance-influencing factors.

Structure and operation of plate heat exchangers

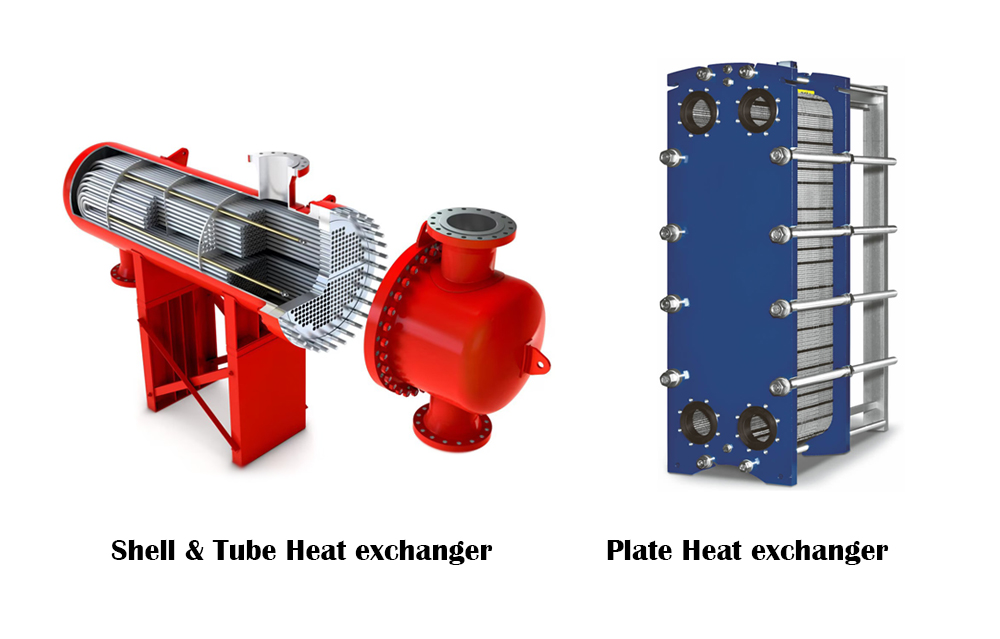

Plate heat exchangers consist of a series of thin, corrugated metal plates arranged parallel to each other inside a frame. These plates are typically made of stainless steel to ensure sufficient resistance to corrosion and operational pressure. Hot and cold fluids flow alternately between the plates, with heat being transferred through the thin plate walls.

The corrugated design of the plates induces turbulent flow, significantly enhancing the heat transfer coefficient. This makes plate heat exchangers highly efficient for applications with small temperature differences between fluids. Furthermore, their compact design optimizes space usage and allows for design flexibility. By simply adding or removing plates, the heat exchanger’s capacity can be easily adjusted, which is particularly valuable in industries like food or pharmaceuticals that require periodic process changes.

Structure and operation of shell-and-tube heat exchangers

Shell and tube heat exchangers are composed of a cylindrical shell and a bundle of tubes. One fluid flows through the tubes, while the other flows through the shell side (the space between the tubes and the shell). Thanks to their robust design and ability to withstand high pressures and temperatures, they are widely used in heavy industries such as refineries and power plants.

The tubes may be straight or U-shaped, and baffles are commonly used to direct the fluid flow inside the shell and enhance thermal performance. Baffles also promote turbulence and help prevent mechanical damage to the tubes. While this structure enables large-scale heat transfer, it requires more space than plate heat exchangers. However, shell and tube exchangers offer high design flexibility and customization potential to meet specific operational requirements.

Thermal efficiency comparison: Heat transfer coefficient

The heat transfer coefficient is a key metric for evaluating the thermal performance of heat exchangers. In plate heat exchangers, the unique corrugated plate design and induced turbulence result in much higher heat transfer coefficients compared to shell-and-tube exchangers. This makes them ideal for low-temperature-difference applications. Conversely, shell-and-tube exchangers perform well in applications with large temperature differences between fluids.

The tubular structure and use of baffles support high-volume heat transfer, although design limitations—such as tube wall thickness—typically lead to lower heat transfer coefficients. However, techniques like adding fins or using turbulators can improve this. Additionally, the thin walls in plate heat exchangers result in lower thermal resistance and faster heat transfer, whereas thicker tube walls and potential fouling in shell-and-tube designs can increase thermal resistance and reduce efficiency.

Pressure drop and its impact on performance

Pressure drop is another critical factor affecting heat exchanger performance, closely linked to the energy consumption of pumps or fans. Due to narrow channels and induced turbulence, plate heat exchangers typically experience higher pressure drops than shell-and-tube exchangers. This may necessitate stronger pumps and lead to higher operational costs. Shell-and-tube exchangers generally have lower pressure drops, especially with designs featuring fewer passes. However, a large number of baffles or small-diameter tubes can increase pressure drop, making optimal design choices—like tube arrangement and baffle count—essential.

In systems where minimal pressure drop is crucial, such as HVAC, shell-and-tube exchangers may be more suitable. On the other hand, for applications prioritizing thermal performance, plate heat exchangers are often preferred.

Temperature and pressure tolerance

A major difference between the two types lies in their temperature and pressure tolerance. Shell-and-tube exchangers, made from materials like carbon steel or high-strength alloys, can handle very high temperatures (up to 500°C) and pressures (up to 35 bar or more), making them ideal for demanding conditions in refineries and power plants.

In contrast, plate heat exchangers are typically suited for medium to low pressures (up to 25 bar) and lower temperatures (up to 250°C). Welded plate designs can enhance their resistance to temperature and pressure but may reduce design flexibility and ease of maintenance. Plate heat exchangers are often a better choice in food and pharmaceutical industries, where corrosion resistance, hygienic design, and moderate temperatures are required.

Ease of maintenance

Easy maintenance is a major advantage of plate heat exchangers. Their plates can be easily removed from the frame, allowing for quick inspection and cleaning. This is especially important in industries prone to fouling or contamination. In contrast, shell-and-tube exchangers are harder to maintain. Accessing the internal tubes is more difficult, and cleaning often requires mechanical or chemical methods, which are more time-consuming and costly.

Designs like floating head shell-and-tube exchangers offer easier access for maintenance but increase initial costs. Additionally, in case of damage, individual plates in plate exchangers can be replaced quickly, while tube bundle repairs or replacements in shell-and-tube exchangers are more complex and expensive.

Industrial applications and limitations

Plate heat exchangers, due to their compact design and high thermal efficiency, are widely used in food, pharmaceutical, HVAC, and domestic heating systems. They are particularly suitable for low-to-medium viscosity fluids and applications requiring flexible thermal capacity. In contrast, shell-and-tube exchangers are prevalent in heavy industries such as oil and gas, petrochemicals, power generation, and steam production. They are better suited for high-viscosity fluids, high temperatures, and large volumes.

Limitations such as fouling sensitivity in plate exchangers and higher maintenance costs in shell-and-tube exchangers must be considered when selecting a heat exchanger based on the specific operational conditions of each project.

Impact of fouling on thermal performance

Fouling is a significant challenge in heat exchanger performance that can greatly reduce efficiency. In plate heat exchangers, the narrow channels and turbulent flow minimize fouling compared to shell-and-tube designs. Moreover, the easy-cleaning feature of plate exchangers allows for quicker and cheaper fouling removal.

In shell-and-tube exchangers, fouling—especially inside the tubes—can increase thermal resistance and lower efficiency. Use of turbulators, appropriate material selection, and good design practices can reduce fouling, but maintenance remains more complex compared to plate heat exchangers.

Capital and operating costs

Plate heat exchangers generally have higher initial costs due to the use of high-quality materials and more complex manufacturing processes. However, their superior efficiency and compact design can reduce long-term operational costs, such as energy consumption. On the other hand, shell-and-tube exchangers have lower initial costs but may incur higher maintenance, repair, and energy expenses over time. A detailed cost-benefit analysis can help determine the best option for each project.

Sustainability and environmental impact

Plate heat exchangers have lower environmental impact due to their compact design, higher efficiency, and lower energy consumption. The use of recyclable materials like stainless steel also enhances their sustainability. Shell-and-tube exchangers, with their larger size and higher energy use, may have a greater environmental footprint, although their long service life can help offset some of this. In both types, the integration of modern technologies aimed at improving energy efficiency and reducing emissions is increasingly important.

Choosing the right heat exchanger for your needs

The choice between plate and shell-and-tube heat exchangers depends on the specific needs of the project. Where space is limited, high thermal efficiency is essential, and ease of maintenance is a priority, plate heat exchangers are a better option. Conversely, for applications requiring high temperature and pressure resistance, large fluid handling, or operation in harsh environments, shell-and-tube exchangers are more appropriate. Factors such as fluid type, operating conditions, hygienic requirements, available space, and budget must all be considered. Consulting with experts and conducting technical and economic analyses can lead to an optimal decision.

References

- Alfa Laval. (2023). “Plate Heat Exchangers: Design and Applications.” Retrieved from www.alfalaval.com

- Engineering Toolbox. (2024). “Shell and Tube Heat Exchangers.” Retrieved from www.engineeringtoolbox.com

- Heat Transfer Engineering Journal. (2022). “Comparative Analysis of Heat Exchanger Performance.” Taylor & Francis Online.

- Process Heating. (2023). “Optimizing Heat Exchanger Efficiency.” Retrieved from www.process-heating.com

- Chemical Engineering Online. (2024). “Advances in Heat Exchanger Design.” Retrieved from www.chemengonline.com