Shell and tube heat exchangers play a vital role in various industries such as oil, gas, petrochemical, pharmaceutical, and power generation. These devices transfer heat between two fluids without direct contact, optimizing process performance and reducing energy consumption. Proper selection and design of these exchangers depend on several factors, and adherence to international standards such as TEMA and ASME ensures their safety and durability. Petrosazeh Beinolmelal Aram Company (Petrosazeh) strictly complies with these standards in its products.

What Is a Shell and Tube Heat Exchanger?

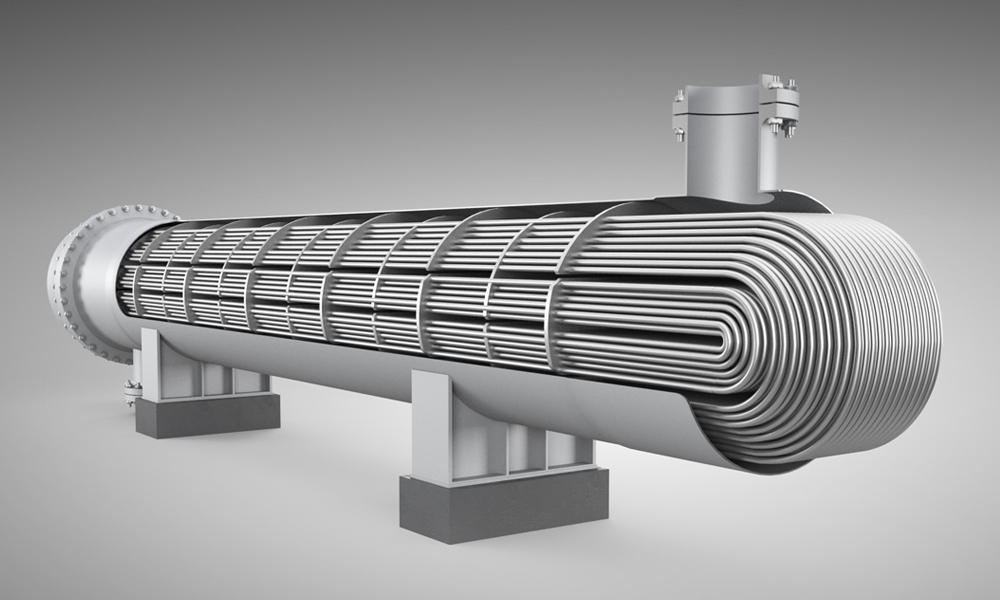

A shell and tube heat exchanger consists of two main components: a metal shell and a bundle of tubes through which the fluids flow. Typically, the hot fluid passes through the tubes, while the cold fluid circulates around them, enabling effective heat transfer. This simple yet flexible design makes shell and tube exchangers suitable for a wide range of applications—from cooling crude oil in refineries to heating processes in the food industry.

The main advantage of these exchangers lies in their ability to withstand various pressures and temperatures. Without proper design standards, issues such as leakage, corrosion, and reduced efficiency can occur. Therefore, the TEMA and ASME standards guide engineers in selecting materials, wall thicknesses, joints, and fabrication methods.

Also read: Functioning of shell and tube heat exchangers

TEMA Standard

TEMA (Tubular Exchanger Manufacturers Association) provides a comprehensive guide for the design, construction, and maintenance of shell and tube heat exchangers. Established in 1939, this standard has been continuously updated and is globally recognized for its precision and completeness.

TEMA classifies heat exchangers into three main types:

- Type C (Commercial): Designed for moderate pressure and temperature applications using non-corrosive fluids. Due to simple construction of tubes, baffles, and heads, it offers lower manufacturing costs—ideal for general industrial uses such as water or oil cooling in light-duty systems.

- Type N (Chemical): Intended for chemical processes involving corrosive fluids. Resistant materials and special components minimize corrosion and damage—ideal for the chemical and pharmaceutical industries.

- Type R (Refinery): Designed for high-pressure and high-temperature operations in refineries, such as hydrocracking or crude oil treatment units, providing strength and durability under harsh conditions.

TEMA also specifies detailed requirements for components such as tube sheets, baffles, and heads, including wall thicknesses, welding methods, and non-destructive testing procedures to ensure safety and long service life.

TEMA Design Configurations

- AES: Removable head with single-pass shell and cross baffles; suitable for high temperatures and easy cleaning.

- BEM: Fixed head with welded tube sheet; economical and suitable for medium pressure.

- NEN: Corrosion-resistant design for chemical processes using special alloys for high durability.

Selecting the appropriate type of heat exchanger depends on factors such as fluid type, pressure, temperature, maintenance requirements, and manufacturing cost.

ASME Standard

The ASME (American Society of Mechanical Engineers) Boiler and Pressure Vessel Code, particularly Section VIII, is one of the most important standards for the design of shell and tube heat exchangers. It outlines strict requirements for design, fabrication, inspection, and testing of pressure vessels and heat exchangers.

ASME Section VIII is divided into three divisions:

- Division 1: General design for medium pressure.

- Division 2: Advanced design for high pressure with detailed engineering requirements.

- Division 3: Very high-pressure design applications.

ASME focuses on precise engineering calculations, material selection, wall thickness determination, and welding techniques, while mandating non-destructive examinations such as radiography and ultrasonic testing to prevent structural defects and ensure long service life.

Materials Used in Shell and Tube Heat Exchangers

Material selection depends on fluid type, temperature, pressure, and environmental conditions. Common materials include:

- Carbon Steel: Cost-effective, suitable for general use; requires coating for corrosive environments.

- Stainless Steel: Corrosion-resistant; ideal for food, pharmaceutical, and acidic fluids.

- Nickel and Titanium Alloys: Excellent for high-temperature and corrosive environments; titanium offers light weight and strength but is more expensive.

Both TEMA and ASME recommend material selection based on compatibility with fluids, pressure, and temperature, supported by chemical and mechanical testing to ensure quality.

Design Requirements and Engineering Calculations

Design involves precise calculations for wall thickness, baffle spacing, and tube sheet layout. Baffles direct the fluid flow, improving heat transfer. TEMA provides various baffle designs for different conditions, as incorrect baffle design can cause inefficiency or mechanical failure.

Proper tube-to-tube sheet connections prevent leakage, and adherence to welding standards ensures long-term durability.

Testing and Inspection Requirements

TEMA and ASME emphasize non-destructive tests such as radiography, ultrasonic testing, and hydrostatic pressure tests to detect cracks or weld defects.

The hydrostatic test verifies the vessel’s ability to withstand design pressure. TEMA also includes requirements for periodic inspections during the service life of exchangers to ensure continued safe performance.

Visual and dimensional inspections are essential for verifying fabrication quality and minimizing unexpected repair costs.

Applications of Shell and Tube Heat Exchangers

Due to their strength, versatility, and pressure-temperature resistance, these exchangers are used in:

- Refineries and Petrochemical Plants: For heating crude oil, cooling products, heat recovery, and distillation processes.

- Power Plants: Used for cooling water, steam, and oils in thermal and combined-cycle systems (e.g., HRSG units).

- Chemical Industries: For heating/cooling of reactive or corrosive fluids, ensuring stable and safe operation.

- Food and Pharmaceutical Industries: In pasteurization, sterilization, cooling, and energy recovery systems—designed hygienically to prevent contamination.

Differences Between TEMA and ASME

TEMA: Focuses specifically on shell and tube exchangers, providing detailed component-level guidance and practical design recommendations.

ASME: Broader scope covering all pressure vessels, focusing on global safety and precise engineering calculations.

Safety and Maintenance Considerations

Safety includes the installation of relief valves, pressure control systems, and non-destructive testing. Maintenance involves tube cleaning, corrosion checks, and staff training to identify potential issues early. TEMA and ASME provide detailed maintenance guidelines to extend equipment life.

Key Factors in Selecting a Shell and Tube Heat Exchanger

Selecting a suitable heat exchanger requires attention to several factors:

- Fluid Type: Corrosive fluids require resistant materials.

- Pressure and Temperature: Must comply with TEMA and ASME limits.

- Cost and Maintenance: Economical models may require more frequent servicing.

- Industrial Application: The exchanger type must match process needs.

Read more: Guide to shell and tube heat exchangers design

Conclusion

The TEMA and ASME standards ensure quality, performance, and safety in the design of shell and tube heat exchangers. Petrosazeh Beinolmelal Aram adheres strictly to these standards, delivering high-performance and long-lasting products for various industrial applications.

References:

- hcheattransfer.com/shell_and_tube.html/

- tema.org/standards/

- asme.org/codes-standards/about-standards/

- thomasnet.com/articles/pumps-valves-accessories/shell-tube-heat-exchangers/

- chemengonline.com/shell-and-tube-heat-exchangers/

- enggcyclopedia.com/2011/05/tema-shell-tube-heat-exchanger-classes/

- engineeringtoolbox.com/heat-exchanger-equation-d_435.html/

- epc.com/blog/tema-vs-asme-heat-exchanger-standards/