Proper selection of storage tanks and pressure vessels has a direct impact on equipment performance, operational safety, and maintenance costs. These components play a vital role in the oil, gas, petrochemical, and chemical industries, and making the right decision regarding their type, material, and design can significantly improve efficiency and operational lifespan.

Petrosazeh Beinolmelal Aram (Petrosazeh), with its experience in designing and manufacturing such equipment, has prepared this guide to assist engineers and project managers in making informed decisions.

This document explores the differences, standards, materials, safety considerations, and key selection factors for storage tanks and pressure vessels, helping you choose the most suitable type for your industrial needs.

Main Differences Between Storage Tanks and Pressure Vessels

Storage tanks are designed to hold liquids or gases at near-atmospheric pressure, primarily providing sufficient capacity without requiring high pressure resistance.

In contrast, pressure vessels are designed to contain materials under high internal pressure, requiring the ability to withstand mechanical stresses caused by temperature changes and fluid movement.

Therefore, choosing between storage tanks and pressure vessels depends not only on the volume of material but also on operating conditions, fluid type, and required pressure. Factors such as construction material, wall thickness, geometry, and auxiliary equipment all influence safety and performance.

Types of Storage Tanks

Storage tanks are essential components in industrial systems for holding liquids, gases, or chemicals under various conditions. These tanks, as part of the broader category of storage and pressure vessels, are classified by shape, structure, and application, including:

- Spherical and cylindrical tanks

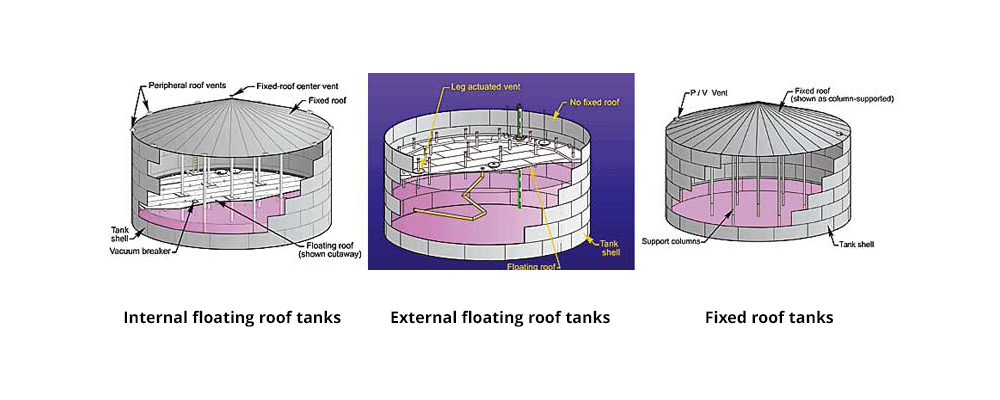

- Fixed roof tanks

- Floating roof tanks

- Dome roof tanks

- Cone roof tanks

The appropriate type depends on factors such as the stored substance, operating pressure, environmental conditions, and installation space.

Spherical Tanks

Due to their geometric shape, spherical tanks evenly distribute internal stresses, making them ideal for storing gases or liquids under high pressure. They require less material for the same strength compared to cylindrical tanks. These are commonly used for propane, butane, or ammonia storage.

However, their manufacturing process is complex and expensive, so they are typically used in applications where safety and pressure resistance are top priorities. Petrosazeh manufactures spherical tanks in compliance with international standards such as ASME, ensuring superior safety and efficiency.

Cylindrical Tanks

Cylindrical tanks are the most common type of storage tanks, valued for their ease of fabrication and design flexibility. They are used across various industries, including oil, gas, agriculture, and pharmaceuticals.

These tanks can be constructed in horizontal or vertical orientations:

- Vertical tanks are space-efficient and offer better stress distribution.

- Horizontal tanks are easier to transport and suitable for smaller capacities.

They can also be fitted with mixers, heating coils, or heat exchangers for process integration.

Fixed Roof and Floating Roof Tanks

Fixed roof tanks are used for non-volatile substances such as water, heavy oils, or certain chemicals. Their enclosed roofs prevent evaporation and protect against weather conditions like rain and wind.

Conversely, floating roof tanks are designed for volatile liquids such as crude oil, gasoline, and light hydrocarbons. The floating roof moves with the liquid level, minimizing vapor space and reducing evaporation losses and explosion risks.

Dome Roof Tanks

Dome roof tanks feature a unique dome-shaped top that provides excellent resistance to external loads such as wind and snow. These are suitable for harsh environmental conditions and are widely used in petrochemical facilities and water storage systems.

The aerodynamic design distributes external forces evenly, reducing the need for internal support structures.

Cone Roof Tanks

Cone roof tanks have sloped roofs that facilitate the drainage of rain or snow. They are commonly used for storing dry materials like grains or solid chemicals, but can also be adapted for certain liquids. The sloped design prevents debris accumulation and simplifies maintenance.

Choosing the Right Type of Storage Tank

Tank selection should be based on project-specific needs:

- Spherical tanks: ideal for high-pressure applications.

- Dome roof tanks: suited for harsh environments.

- Cylindrical and cone roof tanks: more economical for general use.

Key considerations include fluid type, budget, space constraints, and safety requirements. Petrosazeh provides technical consulting and custom tank manufacturing to help clients choose the most appropriate equipment.

Also read: Principles of storage tank and pressure vessel design

Pressure Vessels and the Role of Design in Safety

Pressure vessels must withstand internal pressure and mechanical stresses caused by temperature and fluid movement.

The spherical design provides even pressure distribution and minimizes material usage but is more costly to produce. Cylindrical vessels are more common and can have elliptical, hemispherical, or flat heads, suitable for applications such as boilers, heat exchangers, and chemical reactors.

Orientation also affects functionality:

- Horizontal designs simplify cleaning and liquid separation.

- Vertical designs offer better mixing and space utilization.

Selection should be based on fluid properties, environmental conditions, and maintenance accessibility.

Materials and Their Impact on Performance

Common materials used in storage tanks and pressure vessels include:

- Carbon steel: Economical and durable but requires coatings for corrosive environments.

- Stainless steel: Corrosion-resistant, ideal for food, pharmaceutical, and chemical industries.

- Nickel and titanium alloys: Excellent resistance to high temperature, pressure, and corrosive substances, though expensive.

- Composite and FRP materials: Lightweight, corrosion-resistant, and suitable for specialized industries such as aerospace.

Material selection should consider pressure, temperature, fluid type, and environmental factors, along with mechanical properties like tensile strength and flexibility.

Standards and Regulations

Compliance with international standards ensures equipment safety and reliability.

Key standards include:

- ASME Section VIII: for pressure vessels

- API 650/620: for storage tanks containing oil and petroleum products

Following these standards reduces operational risks, ensures export compliance, and extends equipment lifespan.

Safety and Operational Maintenance

Safety begins with precise design but depends heavily on continuous maintenance.

Essential measures include:

- Non-destructive testing (NDT)

- Corrosion and leakage inspections

- Digital monitoring of pressure and temperature conditions

Easy access to equipment, especially in large tanks and pressure vessels, helps minimize unexpected shutdowns and maintenance costs.

Equipment Selection Process

Equipment selection should follow a systematic approach:

- Define required volume and pressure.

- Select suitable materials and design based on standards.

- Identify a reliable manufacturer for production and installation.

This structured process ensures equipment that is operationally suitable, durable, and efficient.

Conclusion

Selecting the right storage tanks and pressure vessels must be based on thorough technical analysis, standard compliance, and operational conditions. Proper design, material selection, and modern engineering solutions guarantee optimal performance and long-term safety.

Petrosazeh, through specialized consulting and customized fabrication, enables clients to make informed and reliable decisions for their industrial operations.

References:

- gpi-tanks.com/a-comprehensive-guide-to-pressure-vessels-all-you-need-to-know/

- buckeyefabricating.com/ultimate-guide-to-choosing-your-pressure-tank-materials/

- safetyculture.com/topics/pressure-vessel/

- savannahtank.com/types-of-storage-tanks/

- stalwartint.com/the-ultimate-guide-to-high-pressure-vessel-selection/

- ironcladenvironmental.com/2023/07/10/chemical-storage-tanks-a-complete-guide/

- holykell.com/news/Comprehensive-Guide-to-Storage-Tank-Types-and-Measuring-Instrumentation.html/

- venwiz.com/blog/how-do-you-select-the-perfect-material-for-your-pressure-vessel/