Double pipe heat exchangers are among the simplest yet most efficient heat transfer equipment, holding a special place in various industries, especially oil and gas. Due to their simple design, low manufacturing cost, ease of maintenance, and high flexibility in diverse applications, they are widely used in industrial processes. This article provides a comprehensive review of the types of double pipe heat exchangers, their applications, advantages, disadvantages, and a comparison with other heat exchanger types. The goal is to provide accurate information for engineers and enthusiasts in this field.

What Is a Double Pipe Heat Exchanger?

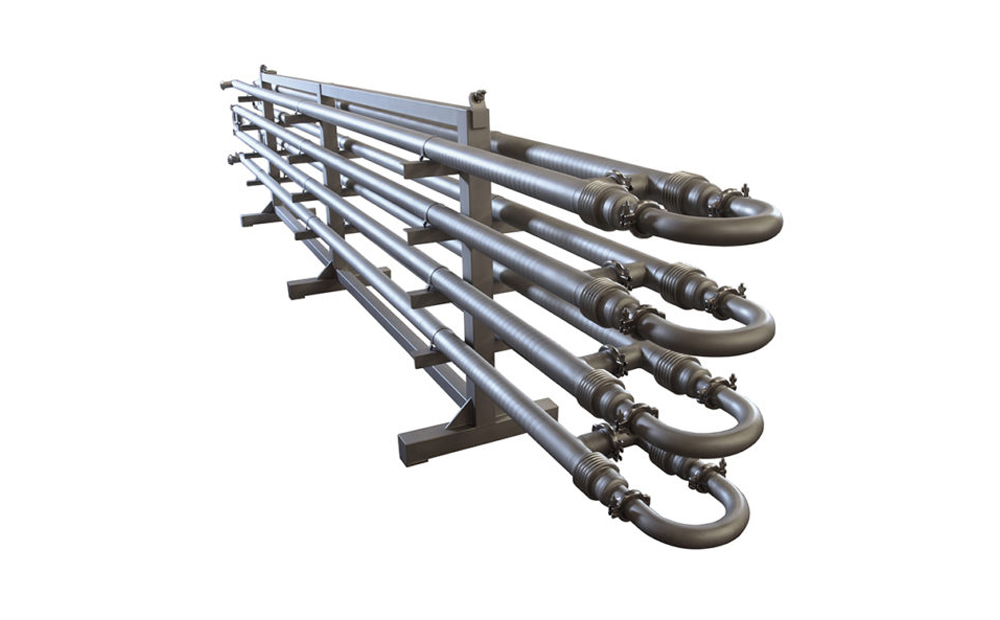

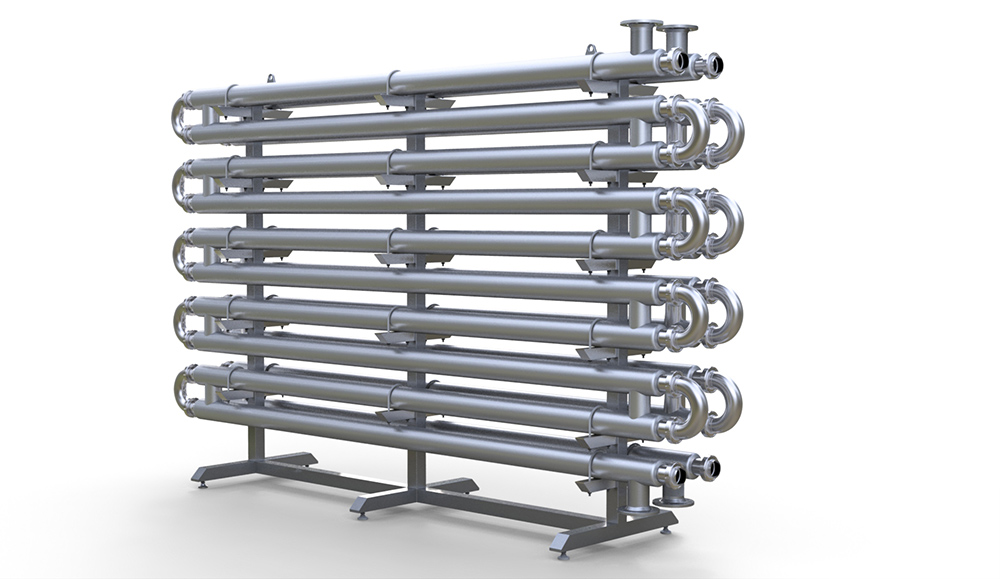

A double pipe heat exchanger consists of two concentric pipes with different diameters. Fluids flow through the inner pipe and the annular space between the two pipes without mixing, enabling heat transfer between two fluids of different temperatures.

Due to their low construction cost and simple design, these heat exchangers are suitable for applications with low flow rates and compact size requirements. They are typically used under medium pressure and temperature conditions and are found in industries such as oil, gas, petrochemicals, and HVAC systems. Their ease of installation and maintenance makes them an ideal choice for cost-sensitive projects.

At Petrosazeh International Company (IPS), double pipe heat exchangers are designed according to global standards and modern technical knowledge, and are manufactured using materials such as stainless steel, copper, or special alloys based on specific operational conditions.

Types of Double Pipe Heat Exchangers

Double pipe heat exchangers can be categorized based on flow configuration, design, and application. Understanding these types is essential for selecting the right option for various projects.

Parallel-Flow Double Pipe Heat Exchangers

In this type, both fluids flow in the same direction. This leads to a gradual decrease in temperature difference along the exchanger, potentially reducing thermal efficiency. However, it reduces thermal stresses and prevents cracking, making it suitable for applications with limited temperature differences.

Petrosazeh uses this design in processes such as preheating in refineries, where simplicity and safety take precedence over maximum efficiency.

Counter-Flow Double Pipe Heat Exchangers

Here, fluids flow in opposite directions. This arrangement maintains a relatively constant temperature difference throughout the exchanger, maximizing heat transfer. It is especially effective in conditions that require high efficiency and have limited space.

Despite its high efficiency, this model requires more precise design due to the risk of thermal stresses from large temperature differences. Petrosazeh manages this challenge by selecting materials carefully.

Double Pipe Heat Exchangers with External Fins

To enhance heat transfer area, some designs incorporate external fins on the pipes. These fins increase the contact surface with the fluid and are effective for fluids with low heat transfer coefficients, such as gases.

This model is commonly used in HVAC systems or refinery gas cooling. However, fins may increase fouling, thus requiring more frequent cleaning, which must be considered in maintenance plans.

Applications of Double Pipe Heat Exchangers

Due to their simplicity and adaptability, double pipe heat exchangers are used in a wide range of industries.

Oil and Gas Industry

In this sector, these exchangers are used for preheating oil, cooling process gases, and energy recovery. Their compact design enables use in mobile or space-constrained units.

At Petrosazeh, exchangers are designed according to API and TEMA standards to ensure optimal performance in harsh operational conditions. Their cost-effectiveness makes them ideal for budget-conscious projects.

HVAC and Refrigeration

In these systems, tube to tube heat exchangers transfer heat between refrigerants and cooling fluids. Due to their small size and ease of installation, they are widely used in chillers and residential and industrial cooling systems.

Their simple design and easy maintenance make them highly attractive for service companies and end-users.

Chemical and Pharmaceutical Industries

In sensitive processes such as chemical reactions or drug manufacturing, precise temperature control is essential. Double pipe heat exchangers, with corrosion-resistant materials, are an ideal choice in such settings.

Petrosazeh designs these units using high-quality materials and in compliance with sanitary standards to meet the specific needs of these industries.

Also read: What is double pipe heat exchanger and its role in refineries

Advantages of Double Pipe Heat Exchangers

Simple Design and Low Cost: Minimalist design reduces manufacturing, installation, and maintenance costs. As a result, they are excellent options for low-budget or fast-track projects. Easy access to pipes reduces repair time and increases reliability.

Flexibility in Design: Options in material selection, flow configuration, and pass arrangements make these exchangers adaptable to a wide range of operational conditions. This allows for custom designs and performance optimization in special projects.

Resistance to Pressure and Temperature: With proper design and durable materials, these exchangers perform reliably under harsh thermal and pressure conditions, which is especially valuable in the oil and gas sector.

Disadvantages of Double Pipe Heat Exchangers

Low Efficiency at High Volumes:

Designed for low to moderate flow rates, these exchangers are not cost-effective at large scales. Using multiple units in series or parallel can improve performance but increases cost and system complexity.

Space Requirements:

Compared to plate exchangers, these units take up more space, especially in multi-pass or finned configurations, which can be limiting in compact installations.

Fouling and Maintenance:

Fluids containing suspended particles may cause fouling and reduce efficiency. Turbulence-inducing designs and anti-fouling materials can mitigate this issue to some extent.

Comparison with Other Heat Exchanger Types

Selecting the appropriate heat exchanger requires comparing different types.

Comparison with Shell and Tube Exchangers

Shell and tube heat exchangers perform better in high-volume and complex processes, offering higher thermal efficiency and greater fluid path flexibility.

However, double pipe exchangers, with their simpler design, lower cost, and easier maintenance, are more cost-effective for small-scale or budget-sensitive projects. Petrosazeh recommends the best option based on project-specific needs and limitations.

Comparison with Plate Heat Exchangers

Plate exchangers offer very high efficiency due to compact design and turbulent flow, making them ideal for tight spaces. They also tend to foul less.

Nevertheless, their limited pressure and temperature resistance and higher sensitivity to corrosive or viscous fluids make double pipe exchangers more suitable in some industrial settings like oil and gas. The choice should be based on operational conditions.

Standards and Design Considerations

Design and manufacturing of double pipe heat exchangers must comply with international standards to ensure safety, quality, and performance.

TEMA Standard

TEMA (Tubular Exchanger Manufacturers Association) is a key reference for designing tubular heat exchangers, offering detailed guidelines on design, materials, inspection, and assembly.

Petrosazeh follows TEMA to produce exchangers that are both technically precise and operationally reliable—an essential aspect in demanding energy sector environments.

API Standard

Although API 660 is primarily intended for shell and tube exchangers, many of its principles—like material selection, stress calculations, and testing requirements—apply to double pipe exchangers as well.

Petrosazeh uses this standard as a technical reference to design high-performance exchangers for refinery and petrochemical environments.

Innovations in Double Pipe Heat Exchangers

Recent advancements in materials and design have significantly improved the performance of double pipe exchangers.

Use of Advanced Materials

Alloys such as Inconel, Monel, and nano-coatings improve corrosion and high-temperature resistance, extending service life. These materials provide stable performance in corrosive or high-heat environments.

Petrosazeh integrates these materials to offer long-lasting products with lower maintenance costs.

Heat Transfer Optimization

Designs such as helical tubes, innovative fin geometries, and flow turbulence methods enhance thermal efficiency and reduce overall size.

At Petrosazeh, such technologies are analyzed and implemented using software like HTRI to achieve the highest possible efficiency.

Key Considerations for Selecting a Double Pipe Heat Exchanger

Fluid Type and Operating Conditions: Fluid characteristics—such as type, temperature, pressure, viscosity, and corrosiveness—must be considered in the design. Appropriate material and configuration prevent damage and performance loss.

Capacity and Efficiency Requirements: The exchanger’s capacity should match the required flow and thermal load. For high capacities, multiple exchangers or alternative types may be more suitable.

Cost and Maintenance: Both initial and long-term costs, including maintenance, should be considered. In projects where downtime and maintenance costs are critical, double pipe exchangers are often a smart choice.

Also read: Guide to Choosing Materials for Pressure Vessel Construction

Conclusion

Thanks to their simple design, cost-efficiency, and high adaptability, double pipe heat exchangers hold a special place across many industries. While they have limitations compared to some other types, their ease of maintenance and resilience under various operating conditions make them a practical choice for many projects.

PetroStructure Company (IPS), with its hands-on experience and up-to-date technical expertise, designs and manufactures double pipe exchangers in accordance with international standards. Proper selection requires a clear understanding of project needs and technical conditions—Petrosazeh’s team is ready to provide expert consultation across diverse industries.