Heat exchangers are vital and key components in industrial processes within oil and gas refineries. These equipments facilitate heat transfer between two or more fluids without direct mixing, playing a crucial role in optimizing energy efficiency and enhancing the efficiency of refinery processes. This article examines heat exchangers, their types, and their applications in the oil and gas industry.

What is a Heat Exchanger?

A heat exchanger is a device designed to transfer heat between two or more fluids without mixing them directly. Heat transfer can occur through conduction, convection, or radiation. Heat exchangers come in various designs and structures tailored for specific applications.

Materials Used in Heat Exchangers

One critical aspect of heat exchangers is the materials used in their construction. These materials must withstand corrosion, high pressures, and temperatures. Common materials include stainless steel, nickel alloys, copper, and aluminum. The choice of materials depends on the type of fluids, operating temperatures, and pressures.

Design and Optimization of Heat Exchangers

The design of heat exchangers is crucial for their performance and efficiency. Factors such as fluid flow rates, temperature differentials between fluids, thermal properties of the fluids, and operating pressures are considered in their design. Engineering software such as HTRI (Heat Transfer Research, Inc.) and Aspen Plus are used for simulation and optimization of heat exchanger designs.

Also read: Installation and commissioning of heat exchangers in refineries

Maintenance and Inspection of Heat Exchangers

Regular maintenance and periodic inspection of heat exchangers are essential to ensure optimal performance and prevent sudden failures. Maintenance programs typically include internal and external cleaning, leak checks, inspection of pipes and plates, and pressure testing. Non-destructive testing (NDT) techniques such as ultrasonic and radiographic testing are commonly used to detect internal issues without opening the exchanger.

Innovations and Advances

In recent years, numerous innovations have emerged in the design and construction of heat exchangers. High-efficiency heat exchangers and microchannel heat exchangers are among these innovations. These exchangers offer higher heat transfer surface area and lower thermal resistance compared to traditional exchangers. Additionally, research and development are exploring the use of new materials and nanomaterials to increase corrosion resistance and improve heat transfer efficiency.

Types of Heat Exchangers

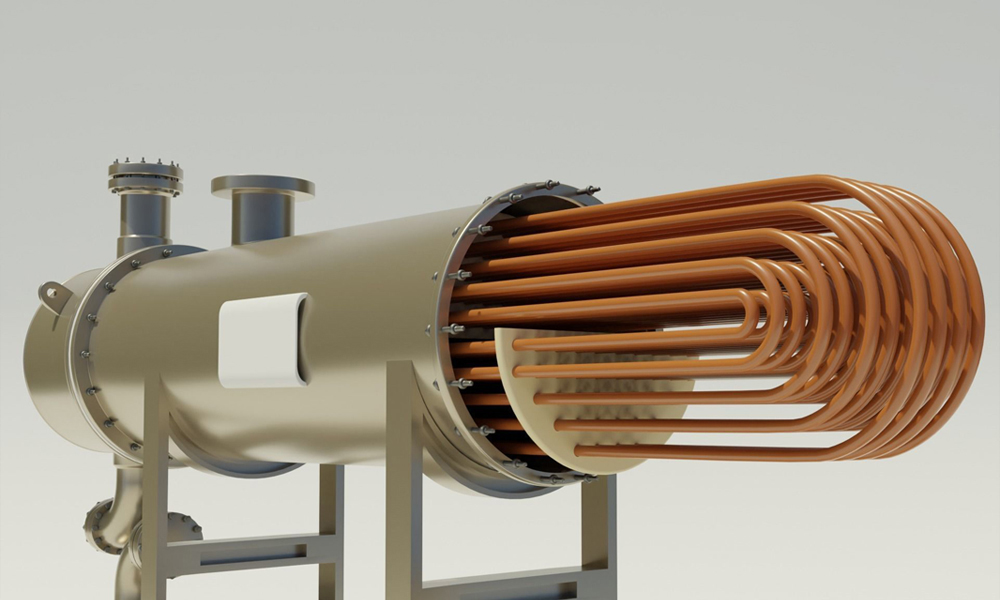

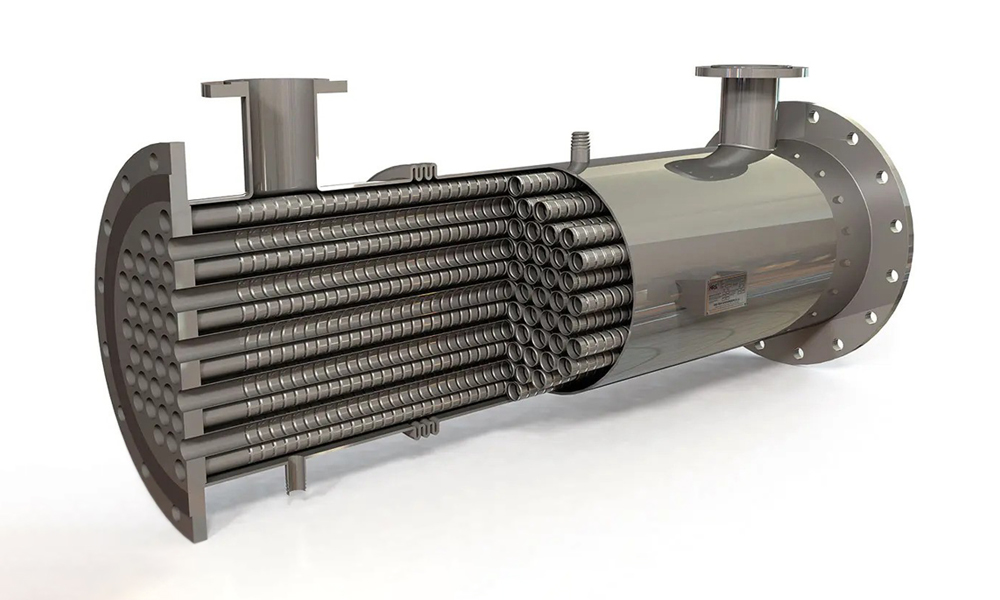

Shell and Tube Heat Exchangers: These consist of a series of tubes inside a shell. One fluid flows through the tubes, and the other flows over the tubes (either inside or outside depending on the design). They are widely used in refineries due to their ability to handle high pressures and temperatures.

Plate Heat Exchangers: These are made up of thin metal plates with gaps between them for fluid flow. Plate heat exchangers are known for their high contact surface area and efficiency, making them suitable for low-pressure applications with relatively low flow rates.

Air Cooled Heat Exchangers: In these exchangers, hot fluid flows through pipes that are cooled by ambient air. Air cooled heat exchangers are suitable for dry and water-scarce areas since they do not require a cooling water source.

Double Pipe Heat Exchangers: These consist of two concentric pipes where one fluid flows through the inner pipe and the other flows through the annular space between the two pipes. They are suitable for applications with low flow rates and large temperature differentials.

Heat exchangers play a critical role in the efficiency and operational reliability of oil and gas refineries, contributing significantly to energy savings and process optimization.

Read more: Types of heat exchangers in refineries

Applications of Heat Exchangers in Oil and Gas Refineries

- Preheating Feedstock: Heat exchangers are used to preheat the feedstock entering distillation towers. This preheating enhances the efficiency of the distillation towers and reduces energy consumption.

- Heat Recovery: In refinery processes, heat exchangers play a crucial role in recovering heat from output streams and reusing it in other sections. This heat recovery saves energy and reduces operational costs.

- Cooling of Final Products: After various refinery processes, final products need to be cooled to suitable temperatures for storage and transportation. Heat exchangers are essential in this cooling process.

- Temperature Control in Chemical Reactions: Precise temperature control is vital for chemical reactions in refinery chemical units. Heat exchangers are used to supply or remove the necessary heat to maintain temperatures within desired ranges.

Advantages of Using Heat Exchangers in Refineries

- Increased Energy Efficiency: Heat exchangers optimize energy consumption in refinery processes by transferring heat between different streams, thereby reducing the need for external energy consumption.

- Reduced Operational Costs: By optimizing energy use and reusing recovered heat, operational costs in refineries are lowered.

- Environmental Protection: Reduced energy consumption and increased process efficiency contribute to lowering greenhouse gas emissions and preserving the environment.

- Improved Safety and Process Efficiency: Heat exchangers help in precise temperature and pressure control in refinery processes, leading to improved safety and efficiency of these processes.

Conclusion

Heat exchangers are integral components of oil and gas refineries, playing a crucial role in optimizing energy use, reducing operational costs, and improving process efficiency. From preheating feedstocks to cooling final products and recovering heat, these equipments are utilized in all stages of oil and gas refining. By selecting the appropriate type of exchanger and optimizing its design, refineries can achieve higher efficiency and experience significant positive economic and environmental impacts.