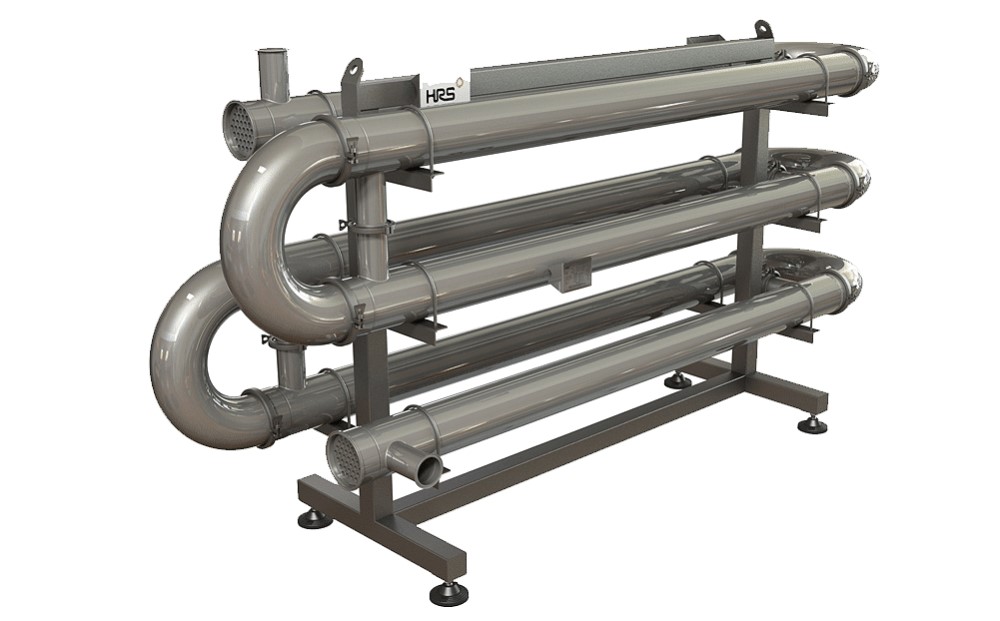

A double pipe heat exchanger is one of the types of heat exchangers, widely used in industrial applications, particularly in refineries, due to its simple design, high efficiency, and flexibility. This heat exchanger consists of two coaxial pipes, one placed inside the other. The fluid that needs to be heated or cooled flows through one of these pipes, while the other fluid flows through the annular space between the two pipes. This design enables efficient heat transfer between the two fluids without mixing them.

Structure and Working Principle of a Double Pipe Heat Exchanger

The structure of double pipe heat exchanger includes an inner pipe and an outer pipe arranged along each other. The hotter fluid flows through one of these pipes and transfers its thermal energy through the metal wall to the cooler fluid inside the other pipe. This heat transfer occurs based on conduction and convection principles.

Fluid flow can be either:

- Co-current flow: Both fluids flow in the same direction.

- Counter-current flow: The hot and cold fluids flow in opposite directions, which improves the heat transfer efficiency.

Advantages of Double Pipe Heat Exchangers

Simple and low-cost design: The structure of this heat exchanger is straightforward, and its production and maintenance costs are lower compared to other types.

Easy installation and setup: Due to its linear design, it can be easily utilized in various systems.

High flexibility: Capacity can be increased by connecting several exchangers in series or parallel.

Easy maintenance: Cleaning and replacing parts are simpler compared to other types of heat exchangers.

Disadvantages of Double Pipe Heat Exchangers

Limited heat transfer capacity: Compared to larger exchangers, such as shell and tube heat exchangers, it has a lower efficiency and is not suitable for high-volume processes.

Faster fouling: In fluids with suspended particles, clogging can occur in the inner pipe, requiring frequent cleaning.

Lower resistance to high pressure and temperatures: Under extremely harsh operational conditions, this type of heat exchanger may not perform optimally.

Uses of Double Pipe Heat Exchangers in Refineries

Refineries are complex environments where heat transfer management plays a key role. tube to tube heat exchangers are used in this industry for several reasons, including:

Energy recovery: These exchangers can transfer heat from outgoing fluids to incoming fluids, saving energy.

Compact space requirement: They occupy less space compared to some other types of exchangers, making them suitable for confined environments.

Temporary or emergency processes: Due to their simple design, they can be used in temporary or portable units in refineries.

Practical Applications in Refineries

- Crude oil cooling: After the initial processing stages, the hot crude oil must be cooled before entering the next steps, where this heat exchanger plays a role.

- Heating process fluids: In certain units, hot steam flows through the inner pipe, warming other fluids in the annular space.

- Pre-heating input materials: Heat from outgoing fluids can be used to preheat incoming fluids, optimizing energy consumption.

Design Principles for Double Pipe Heat Exchangers

The design of a double pipe heat exchanger requires careful consideration of several key parameters. The first step is to determine the properties of the fluids involved in the process, including fluid type, temperature, pressure, and flow rate. This information is essential for selecting the appropriate pipe diameter, length, and wall thickness. The main goal is to maximize the heat transfer rate while minimizing pressure drop and improving system efficiency.

Choosing the right materials for constructing these exchangers is also crucial. In industrial environments like refineries, where fluids may be corrosive, materials such as stainless steel, nickel alloys, or titanium are commonly used. Depending on operational needs, internal baffles can be employed to increase the heat transfer surface area. The choice between co-current and counter-current flow should be based on process conditions and the need to optimize heat transfer.

To design and optimize performance, engineering software such as Aspen HYSYS and HTRI are commonly used. These tools allow for process simulations, helping engineers improve system performance and reduce issues like fouling.

Maintenance and Optimization of Double Pipe Heat Exchangers

Proper maintenance is crucial for maintaining the efficiency of a tube to tube heat exchanger. One common issue in refineries is fouling of the inner pipe walls, which can reduce heat transfer efficiency and increase pressure drop. To prevent this, periodic cleaning using chemical methods (such as acidic solutions to remove deposits) or mechanical methods (like high-pressure water jets) is recommended.

Performance optimization can include actions such as adjusting fluid flow rates, using anti-fouling materials, or installing filtration systems to prevent suspended particles from entering the exchanger. These measures not only extend the lifespan of the heat exchanger but also improve the overall system efficiency.

Another performance enhancement method is the installation of temperature and pressure sensors for real-time monitoring. These data help operators quickly identify undesirable changes and take corrective actions before major problems occur.

Differences Between Double Pipe Heat Exchangers and Other Heat Exchangers

In comparison with other types of heat exchangers, double pipe heat exchangers have specific features and limitations:

Compared to shell and tube exchangers:

- Advantage: Simpler design, lower cost, and easier maintenance.

- Limitation: Lower heat transfer capacity at high volumes.

- Application: Suitable for systems with low flow rates and greater flexibility needs.

Compared to plate heat exchangers:

- Advantage: Greater resistance to high pressures and corrosive fluids.

- Limitation: Takes up more space, with lower efficiency compared to plate exchangers.

- Application: Suitable for conditions requiring high temperatures and pressures.

In refineries, a combination of these exchangers is often used to achieve maximum efficiency across various processes. The double pipe heat exchanger plays an important complementary role in refinery heating systems.

The Future of Double Pipe Heat Exchangers in the Refining Industry

With advances in technology, the design and performance of double pipe heat exchangers have also improved. The use of new materials, such as nanocomposites, can increase corrosion resistance and improve heat transfer efficiency. Additionally, integrating these exchangers into smart systems based on the Internet of Things (IoT) will enable real-time performance monitoring and automatic adjustments for greater efficiency.

In the future, due to the increasing emphasis on reducing energy consumption and carbon footprints in refineries, more focus will be placed on developing exchangers with higher efficiency. Research into the use of nanofluids (fluids containing metallic nanoparticles) holds promise for significantly improving heat transfer in these types of exchangers.

Conclusion

Despite their simple design, double pipe heat exchangers are among the most effective equipment for thermal energy management in refineries. Due to their low cost, easy installation, and simple maintenance, they are an efficient option for specific applications in the oil and gas refining industry. Although their heat transfer capacity is more limited compared to other exchangers, they are an ideal choice when flexibility and space are crucial.

With future advancements in materials and smart technologies, the performance of these exchangers is expected to improve, making them a vital part of industrial processes. Understanding the principles of design, maintenance, and optimization of these exchangers will help engineers and industry professionals develop better solutions to improve the efficiency of thermal systems.

Read more:

What is a heat exchanger in oil and gas refineries?

References

- ThomasNet: “What is a Double Pipe Heat Exchanger?”

- Chemical Engineering World: “Understanding Double Pipe Heat Exchangers”

- Piping World: “Double Pipe Heat Exchanger Design and Applications”

- ScienceDirect: “Heat Exchanger Basics and Applications in Refineries”

- Engineering Toolbox: “Heat Transfer in Double Pipe Exchangers”