Heat exchanger is fundamental components in industrial processes used for transferring heat between two fluids at different temperatures. These devices are of special importance in the oil and gas industry, as their efficiency can significantly impact productivity and operational costs. Below is a comprehensive overview of heat exchangers from various aspects.

In the oil and gas industry, heat exchangers come in various types, each designed for specific applications. Here are the different types of heat exchangers widely used in this industry:

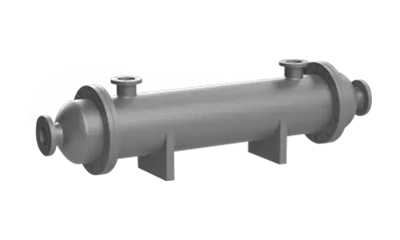

These heat exchangers consist of an external shell and a number of internal tubes. One fluid flows inside the tubes while the other flows outside the tubes and inside the shell. Due to their simple design and ability to withstand high pressure and temperature, they are extensively used in various oil and gas processes, including preheating, cooling, and heat exchange between different fluids. Advantages of shell and tube heat exchangers include high resistance to pressure and temperature and ease of maintenance.

Plate heat exchangers are made up of a series of thin metal plates arranged parallel to each other with minimal spacing. Fluids pass between these plates, and heat is transferred between them. plate heat exchanger is typically used for processes requiring high heat transfer efficiency and compact space, such as heating and cooling fluids with low viscosity. Strengths of this type include a high heat transfer surface area, excellent thermal efficiency, and compact design.

Air cooler heat exchangers consist of a series of tubes carrying hot fluid and a fan that blows cool air over the tubes. This type is particularly useful when access to cooling water is limited or when the cost of liquid cooling is high, such as in remote facilities or dry areas. Key benefits include no need for cooling water and suitability for dry and hot environmental conditions.

Double pipe heat exchangers consist of two concentric pipes, one inside the other. One fluid flows through the inner pipe while the other flows through the annular space between the two pipes. These exchangers are used in processes with low flow rates and high pressures, such as refrigeration systems and certain chemical processes. Advantages include simple design and suitability for high pressures.

Boiling heat exchangers are designed to transfer heat to a fluid until it reaches its boiling point and converts it into steam. These exchangers are used in steam generation processes, refrigeration systems, and heat conversion in petrochemical and refinery units. Benefits include high efficiency in steam production and suitability for industrial applications.

Condensing heat exchangers are designed to cool steam and convert it into liquid. They are used in refrigeration processes, heat recovery from steam, and distillation. Advantages include high efficiency in condensation and energy recovery from steam.

Regenerative heat exchangers feature a fixed or rotating bed of heat storage materials that periodically come into contact with hot and cold flows. They are used in processes that require heat recovery from exhaust gases, such as power generation units and industrial plants. Strengths include high efficiency in heat recovery and reduced energy consumption.

Advantages

This equipment is widely used in various industries such as oil and gas refineries, chemical industries, electric power plants, smelting industry, pharmaceuticals, chemical industries, manufacturing, etc. due to its high heat transfer coefficient, compact structure, easy cleaning and repair capabilities.

Disadvantages

Poor flexibility and easy leakage and the need to periodically replace the washer are the weaknesses of this equipment. Also, due to deposition of dissolved particles and solid materials, deposition due to chemical reaction, corrosion, freezing, etc., a period should be considered for equipment cleaning.

The more fouling the fluid is, the more frequent the cleaning cycles will be.

The manufacturing process of heat exchangers involves several stages, each requiring precision and expertise:

The manufacturing process begins with initial design, which includes thermal and mechanical calculations to determine the size, type, and configuration of the exchanger. Advanced design software such as HTRI and Aspen HYSYS is used for modeling and simulating the performance of heat exchangers.

The materials used must have characteristics such as corrosion resistance, high thermal conductivity, and suitable mechanical strength. Common materials include stainless steel, aluminum, copper, and titanium.

Tubes and plates are usually shaped through processes like bending, pressing, and welding. Final assembly involves connecting the components together and ensuring leak-tightness and mechanical strength.

Heat exchangers undergo pressure, temperature, and performance tests after manufacturing to ensure their quality and safety. Non-destructive testing methods such as ultrasonic testing and eddy current testing are used to identify hidden defects.

Choosing the right materials for manufacturing heat exchangers is crucial and depends on the following factors:

Stainless Steel: Widely used in harsh and corrosive environments due to its high corrosion resistance and ability to withstand high temperatures.

Aluminum: Commonly used in fins and components requiring rapid heat transfer due to its low weight and high thermal conductivity.

Copper: Suitable for applications requiring rapid heat transfer due to its very high thermal conductivity.

Titanium: Used in acidic and alkaline environments due to its exceptional corrosion resistance.

Proper maintenance is crucial for maintaining the efficiency and longevity of heat exchangers and includes the following activities:

Regular Inspection: Periodic inspections to identify leaks, corrosion, and blockages are necessary to maintain the health of heat exchangers and safety of personnel. Non-destructive inspection techniques are employed to assess the internal condition of the exchanger.

Cleaning: Deposits and contaminants should be removed regularly. Cleaning methods include chemical, mechanical, and ultrasonic cleaning. Chemical cleaning is usually employed to remove mineral and organic deposits.

Component Replacement: Worn-out parts such as tubes and gaskets should be replaced promptly to prevent sudden failures.

Heat exchangers do not operate alone and require complementary components, including:

Pumps: Used to transfer fluids into and out of heat exchangers and maintain a steady flow. Depending on process needs, centrifugal pumps and positive displacement pumps are used.

Temperature Controllers: Essential for adjusting and controlling the inlet and outlet fluid temperatures to maintain optimal operating conditions. Thermocouples and PID controllers are widely used as complementary equipment.

Manometers and Pressure Gauges: Used to monitor the pressure inside the exchanger and prevent excessive pressure that could lead to damage. Digital and analog manometers are used for data display and recording.

Valves: Used to control fluid flow and regulate the amount passing through heat exchangers. Common types include ball valves, butterfly valves, and gate valves.

Petro structure company is a manufacturer of heat exchangers. This complex has the possibility of manufacturing heat exchangers by using the expert forces and required equipment. Contact our experts for expert advice.

References