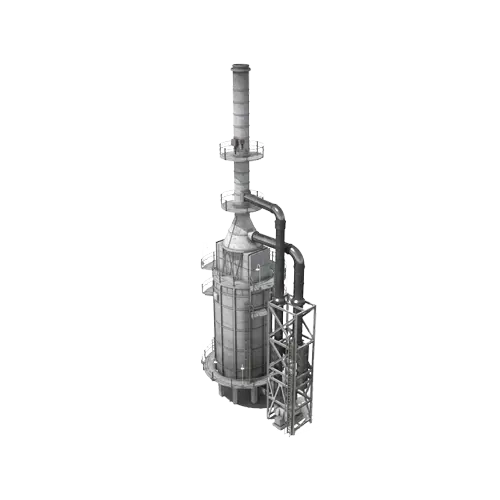

Vacuum tower is one of the vital components in the crude oil refining process, used in the stages of separation and distillation. These towers utilize pressures lower than atmospheric pressure to facilitate the distillation of petroleum materials with high boiling points. This method helps in reducing the boiling temperatures of heavy materials, which leads to improved quality of the final products and a reduction in risks associated with thermal decomposition.

Vacuum tower: It is a device that is used to separate the ingredients of a substance from each other (separation of light hydrocarbons from crude oil or other heavy hydrocarbons), and the separation process is based on the difference in the boiling point of the materials in the operating pressure of the tower (vacuum pressure), which is This principle is based on the mass and heat transfer between the vapor and liquid phases, which takes place in the separation stages, and the phases are gradually purified and separated.

Pressurized tower: It is a device that is used to separate the components of a material from each other (separation of light hydrocarbons from gas condensate or other heavy hydrocarbons) and the separation process is based on the difference in the boiling point of the materials at the operating pressure of the tower (pressure higher than atmospheric pressure). ) based on this, with the transfer of mass and heat between the vapor and liquid phases, which takes place in the separation stages, the purification and separation of the phases is done gradually.

Vacuum Towers reduce the pressure inside the tower using steam or vacuum pumps. This pressure reduction causes heavy petroleum materials, which boil at higher temperatures, to vaporize at lower temperatures. Vacuum Towers are generally divided into two main sections: the upper part where lighter gases are separated, and the lower part that contains heavier materials.

Vacuum towers are generally designed for the separation and distillation of materials under low-pressure conditions. These towers are mainly divided into two broad categories, each having its own specific subtypes:

These towers use various types of trays to perform the distillation and separation processes. Each type of tray has its own specific features and applications:

Features: They have small, mesh-like holes that allow vapor and liquid to pass through.

Advantages: Simple design and relatively low cost.

Disadvantages: Relatively average efficiency and suitable for low to medium loadings.

Features: They have caps placed over the tray holes that create bubble flow of the vapor.

Advantages: Better control of vapor and liquid flow, suitable for complex processes and high loadings.

Disadvantages: Higher cost and complexity, higher pressure drop.

Features: They include adjustable valves to control the flow of vapor and liquid.

Advantages: Precise control of flow and pressure, suitable for high-loading processes.

Disadvantages: More complex design and requires more maintenance.

Features: They have longitudinal slots for the flow of vapor and liquid.

Advantages: Uniform distribution and suitable for medium loadings.

Disadvantages: May be less efficient for very high loadings.

Features: Uses hydraulic systems to control flow.

Advantages: Allows precise control of temperature and pressure.

Disadvantages: More complex design and maintenance.

These towers use packing materials to increase the contact surface between vapor and liquid. The different types of packing include:

Features: Irregularly shaped packing materials that are randomly placed inside the tower.

Advantages: Simple design and lower cost.

Disadvantages: Relatively high pressure drop and moderate efficiency.

Features: Regularly designed and structured packing that provides more contact surface.

Advantages: High efficiency and lower pressure drop.

Disadvantages: Higher cost and more complex design.

Features: Ring-shaped packings that help improve flow distribution and heat exchange.

Advantages: Suitable for various loadings and provides uniform flow control.

Disadvantages: May require more space.

In the operation and practical use of vacuum towers, several key components play a significant role in ensuring effective and efficient performance. These components are specifically designed to enhance the efficiency of distillation and separation under low-pressure conditions.

Trays are generally used for separation and mass and heat transfer between different phases in vacuum towers. Different types of trays include:

Packings are used to increase the contact surface between vapor and liquid in vacuum towers and are divided into two main categories:

Heat exchangers are used for temperature control and preheating or cooling of fluids. They can be of the following types:

Pumps are used to move fluids and create flow in vacuum towers. These pumps may include:

Feed tanks are used to store and feed the input fluids to the tower. These tanks are designed to prepare the fluids in optimal conditions for entry into the tower.

These vanes are used to regulate pressure and prevent vapor leakage in different sections of the tower.

These components are used for discharging final products and regulating various flows within the tower. Nozzles are usually placed in different parts of the tower to manage various outputs.

These devices are used to monitor and regulate the operating conditions of the tower, including pressure and temperature, helping to optimize the process.

In vacuum tower operations, boilers and condensers play crucial roles in the distillation and separation process. These components help regulate temperature and pressure, optimizing the overall performance of vacuum towers. Below, we outline the role of each of these components in the vacuum tower system:

The boiler in vacuum towers is typically used to provide the necessary heat for vaporizing liquids. This heat aids in the evaporation of substances within the tower, thus improving the distillation process. Boilers play particularly important roles in the following areas:

Providing Heat for Evaporation: Boilers supply the heat needed for liquid evaporation and steam production. This steam enters the vacuum tower and facilitates the distillation process. Boilers serve as the primary source of steam production in many industrial processes, and the generated steam is transferred to vacuum towers to carry out the distillation operations.

Temperature Control: Boilers assist in regulating and controlling the temperature of the fluid entering the tower. An appropriate temperature for evaporation and distillation is crucial. With precise temperature control, boilers ensure that the distillation process is conducted under optimal conditions and with high efficiency.

Creating Suitable Pressure: In some cases, boilers can help create the necessary pressure for distillation operations in the vacuum tower, particularly in processes that require higher pressure. Boilers produce steam under pressure, which can help create favorable conditions within the vacuum tower.

The condenser in vacuum towers is used to cool the steam and convert it back into liquid form. This process is essential for the separation and collection of distillation products. Condensers are specifically used in the following ways:

Cooling and Condensing Steam: Condensers cool the steam produced by the boiler and convert it into liquid. This process aids in the collection and separation of distillation products. The hot steam enters the condenser and gradually condenses into a liquid as the temperature decreases. The condensed liquid is then directed to the lower sections of the tower or to a collection system.

Improving Tower Efficiency: By condensing steam, condensers help remove excess steam or impurities from the system, enabling more efficient distillation. Condensers ensure that the various sections of the vacuum tower function correctly and help prevent issues such as blockages or pressure increases.

Controlling Liquid Flow: Condensers help control and regulate the flow of liquid exiting the tower, which can impact the separation process. By converting steam to liquid, condensers assist in collecting and directing the liquid to the desired locations, facilitating subsequent processes.

Using vacuum towers also presents challenges, including the need for regular maintenance, the complexity of the process, and high initial costs. To address these challenges, the use of corrosion-resistant materials, process optimization, and staff training are crucial.

To maintain optimal performance and safety of vacuum towers, regular maintenance and periodic testing are essential. These actions include:

Conclusion

Vacuum towers play a key role in improving the quality and efficiency of oil refining processes. Considering the advantages and challenges discussed, the proper and optimized use of these equipment can help increase productivity and reduce production costs.

Petro structure engineering company is a manufacturer of all kinds of distillation towers (vacuum and under pressure). This complex has the possibility of building all kinds of towers by using the specialized forces and the required equipment. Contact our experts for expert advice.

Sources: