Vacuum tower under pressure

Distillation towers include four main parts:

1. Tower

2. Reboiler system

3. Condenser system

4. Peripheral equipment including: all kinds of control systems, intermediate heat exchangers, pumps and product

Empty Tower

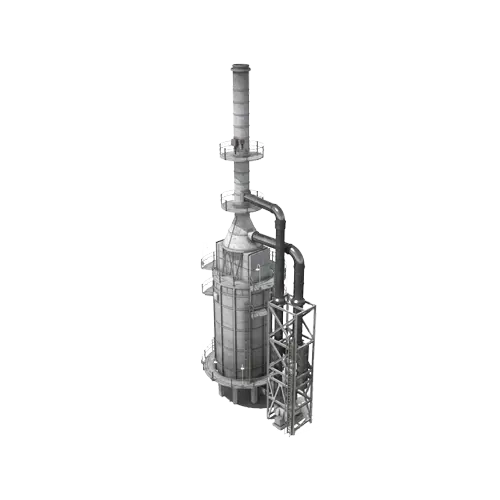

Vacuum tower: It is a device that is used to separate the ingredients of a substance from each other (separation of light hydrocarbons from crude oil or other heavy hydrocarbons), and the separation process is based on the difference in the boiling point of the materials in the operating pressure of the tower (vacuum pressure), which is This principle is based on the mass and heat transfer between the vapor and liquid phases, which takes place in the separation stages, and the phases are gradually purified and separated.

Tower under pressure

Pressurized tower: It is a device that is used to separate the components of a material from each other (separation of light hydrocarbons from gas condensate or other heavy hydrocarbons) and the separation process is based on the difference in the boiling point of the materials at the operating pressure of the tower (pressure higher than atmospheric pressure). ) based on this, with the transfer of mass and heat between the vapor and liquid phases, which takes place in the separation stages, the purification and separation of the phases is done gradually.

The vacuum tower and the distillation tower have been implemented

Installation of vacuum tower

Petrosazeh Beinolmelal Aram Co implements all types of distillation tower, vacuum tower, etc. is. This collection is the best storage tanks in the world with the use of expert staff and modern knowledge Runs atmospheric in the area. Call for expert advice on the implementation and installation of the vacuum tower and the distillation tower