Spherical tanks are one of the types of pressure tanks which, due to their spherical shape, have the ability to withstand higher pressures than cylindrical tanks. These tanks are used to store and transport various gases and liquids, including dangerous nuclear gases, LNG, LPG, etc. In this article, we will introduce and review the design and construction of a spherical tank under pressure.

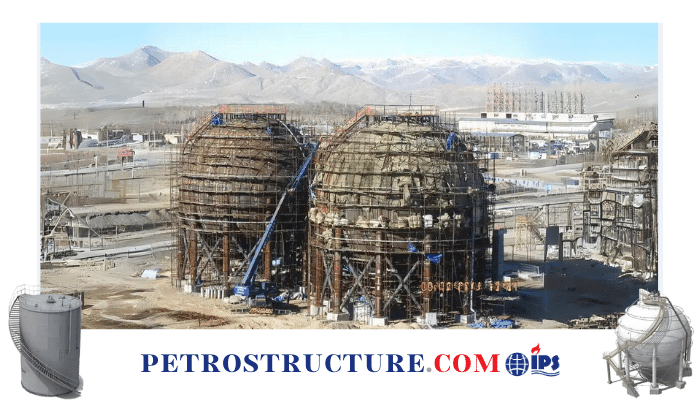

Construction method

Usually, the explosive method is used to make spherical tanks. After welding the tank sheets and performing safety and leakage tests, a controlled explosion is used to create the perfect spherical shape inside the tank.

Use and application

Pressure vessels are used as a vital part of operational units in various industries. These tanks are used in processes such as distillation, drying, filtering and nuclear power plants.

Materials and hazards

The materials stored in these tanks may change phase or turn into gas and change due to pressure and chemical reactions. The possibility of leakage of liquids and gases due to high pressure and chemical reactions requires detailed tests and the implementation of regulatory regulations.

The importance of safety

Considering the possible risks of leakage and fire in spherical tanks, the design should be such that the bending and local stresses are tested and checked before the sheet cracks. Safety standards and regulations are very important for the construction of these tanks.

Material and welding

The use of carbon steel or stainless steel sheets with precise welding and preventing sheet cracking is one of the most important steps in the construction of these tanks. Welders must have the necessary certificates to perform welding.

suitable material

Spherical tanks are made of carbon steel or coated steel sheets that can withstand high stresses and bending along with the high strength of steel. Choosing the right material is one of the important tasks of the tank designer.

Regulations and standards

It is necessary to use safety regulations for the design of tanks. These regulations include many parameters such as working pressure, allowable stress, type of allowable materials and welding codes used in construction.

Tests and quality control

Due to the risks of leakage and fire, accurate tests on spherical tanks are very important. Tests such as leak tests and non-destructive tests are part of the necessary steps in the quality control of tank construction.

Different pressures

In the design of spherical tanks, the design pressure is used more than the working pressure. This value is usually 10% higher than the working pressure of the tank, which is known as the design pressure. Also, hydrostatic pressure is also considered in the design.

Tension analysis

Stress analysis on the tank body is the responsibility of the tank designer and manufacturer. This analysis includes examining the bending and local stresses that are tested before the tank sheet cracks.

Safety regulations

When designing pressure vessels, detailed information about safety parameters such as working pressure, allowable stress, allowable material and welding codes is required. It is necessary to use national and international safety regulations.

The importance of welding

Tank welding plays an important role in the construction of these structures. Insufficient experience of welders or violation of heat treatment may lead to weakening of tensile and creep properties and even cracking of the tank.

Use appropriate sheets

Carbon steel and coated steel sheets, which can withstand high stresses and bending, are chosen for the construction of tanks. The technical information of materials such as wear, corrosion and mechanical strength are also influential in this choice.

Supervision and standards

The use of regulations and safety standards in all stages of construction is of particular importance. Careful monitoring and compliance with regulations guarantee the safety and quality of built tanks.

Conclusion

In this article, we reviewed the design and construction of a spherical tank under pressure. Spherical tanks are considered very vital components in various industries, including oil and gas, petrochemical and power plants, due to their characteristics of bearing high pressures and adapting to high temperatures. Accurate planning, use of appropriate materials, adherence to standards and careful monitoring are of great importance. In this way, spherical tanks will not only perform better, but the risks of leakage and fire will also be minimized.

Petrosazeh Company produces spherical tank, cylindrical tank and other fixed equipment and rotating equipment, as one of the first companies in this field with many years of activity, it is considered one of the most prominent companies in the field of equipment related to oil and petrochemical industries and is proud to Membership in valid vendor lists that include:

A long list of resources of the central body of the Ministry of Oil

Iran’s National Petroleum Products Distribution and Refining Co

National Iranian Oil Engineering and Construction Co

National Petrochemical Co

Company for designing, engineering and supplying parts and chemical materials for petrochemical industries

Oil Industries Engineering and Construction Co

National Iranian Gas Co

Tehran Oil Refining Co

Mapna Co