What is the role of heat exchangers in fixed equipment?

Fixed equipment

Fixed equipment refers to equipment that is fixed during work and process. In fact, this type of equipment is affected by factors such as pressure, weight, contraction, expansion, internal and external stresses, and there are no moving parts in them.

Equipment such as reactors, converters, filters and pressure vessels are classified as fixed equipment.

heat exchanger

Heat exchangers are equipment used for heat exchange between two fluids, heat exchangers play a vital role in heat exchange between two fluids with different temperatures.

This heat exchange can be used to heat, cool or condense fluids in various industrial and chemical processes.

To know exactly what a heat exchanger is and what it is used for, stay with us in this article.

Application of heat exchanger and its types

Heat exchangers are used in cooling and heating processes, so that heat is transferred from one fluid to another due to the temperature difference of two fluids.

The heat exchanger is widely used in air conditioning facilities and industries, textile industries, oil and gas and petrochemical industries, chemical industries, power plants and many other industries in a wide range.

For example, an oil heat exchanger transfers oil heat to water or air, or a pool exchanger transfers hot water heat to pool water.

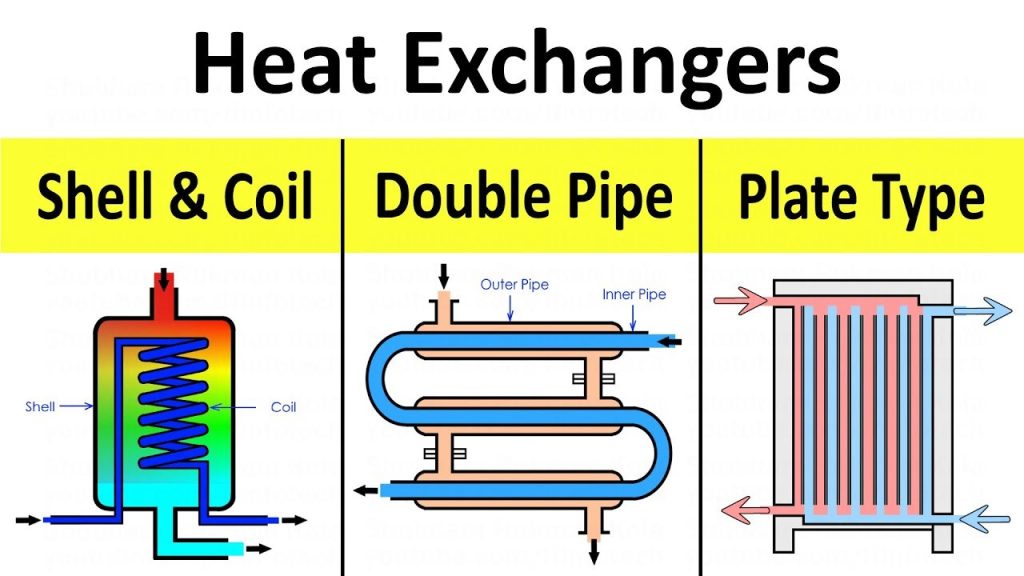

Among the best-selling and widely used types of heat exchangers, shell-tube heat exchangers, air-cooled heat exchangers, and plate heat exchangers can be mentioned.

shell-tube converter:

In this model, which is known as shell and tube, first one fluid passes through a group of tubes that are all connected to one inlet and outlet, and the other fluid enters from the other side of the heat exchanger.

During this process, heat is transferred from the hot fluid to the cold fluid through the walls of the pipes due to the temperature difference between the two fluids. In this way, without direct contact, heat transfer takes place. These converters are often suitable for high temperatures and pressures.

Cooled air exchangers:

In these converters, the air passes around the pipes at a high speed and the fluid flowing in the pipes gives its heat to the environment.

The operation of the automobile radiator is very similar to the heat exchangers, as in the radiator, hot water is flowing, which is cooled by the air blown by the fan.

This converter is used in cases where it is not possible to use water or other cooling liquids.

Plate heat exchanger:

The working method of this converter is in such a way that a number of plates are placed back-to-back, and an empty space is created between them.

There is a hot water flow pipe and a cold water flow pipe, so that one is created in the middle of the fluid in the empty space between the hot and cold fluid plates.

In this way, heat transfer is carried out from the walls of fluid plates. Thermal models are divided into two categories: direct contact and indirect contact.

Applications of heat exchangers in fixed equipment:

Heating and cooling:

Heat exchangers are used to heat fluids in heating systems, such as boilers and air conditioning systems, as well as to cool fluids in cooling systems, such as cooling towers and chillers.

Concentration:

Heat exchangers are used for the concentration of fluids in various industrial processes, such as fruit juice concentration, milk concentration and acid concentration.

Steam production:

Heat exchangers are used to produce steam in boilers and steam boilers, which are used as an energy source in various industries.

Distillation:

Heat exchangers are used in the distillation process to separate liquids with different boiling points, such as separating alcohol from water.

Chemical reactions:

Another application of heat exchangers is to control the temperature of chemical reactions and maintain them at a favorable temperature, in order to increase the speed and efficiency of the reaction.

Conclusion:

Heat exchangers are important fixed equipment in various industries that play a vital role in heat exchange between fluids with different temperatures. Identifying the right model to buy depends on the use of the heat exchanger, its main function, to buy these devices, pay attention to the reliable brand and ensure the authenticity and health of the device.

Petrosazeh, a producer of all types of fixed equipment for the oil and gas industry, spherical pressurized tanks, cylindrical tanks, with years of activity in this field and cooperation with large companies and oil and gas companies, has provided the highest quality spherical tanks in the design and construction of these tanks.

During all the years of its activity, this company has achieved many successes and managed to obtain many certificates.