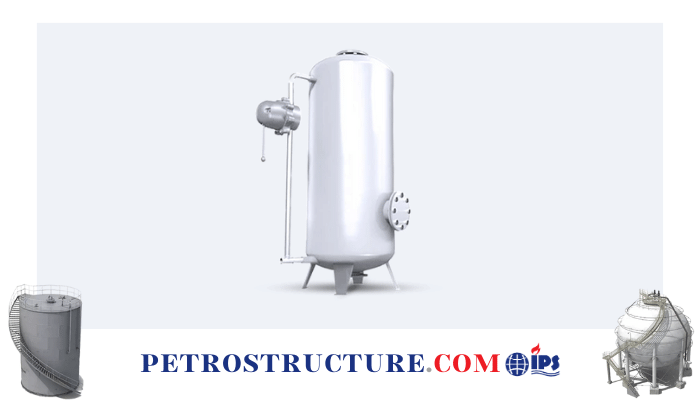

Cylindrical tanks under pressure are one of the vital components in the transfer, storage and management of gases and liquids in the industry. Due to their unique characteristics, these reservoirs play a very important role in industrial progress. In this article, we will examine the role of cylindrical pressure tanks and their impact on the development of the industry.

Cylindrical tank under pressure:

Structure and function:

Pressure cylindrical tank is often made of steel or aluminum and has a cylindrical structure to withstand high pressure.

Role in the maintenance of gases:

These tanks are used as the main tool for storing and transporting gases. Their common applications include storing industrial gases and providing fuel for vehicles.

The role of the cylindrical tank in the industry:

Transfer of gases:

Cylindrical pressure tanks are used in various industries, including gas, petrochemical, and energy industries, as the main means of transporting gases to their final destination.

Storage of dangerous substances:

In some industries that require the storage of hazardous materials, cylindrical pressure tanks are used as a safe and efficient solution to store these materials.

The effect of a cylindrical tank on the safety and productivity of the industry:

Increased security:

Cylindrical pressure vessels with proper safety features help increase security in the industry. These facilities include monitoring and control systems, safety devices, and pressure resistant structures.

Increase Productivity:

The use of high-efficiency cylindrical pressure vessels allows industry managers to improve production and transportation processes and reduce costs.

Challenges and concerns:

Safety and maintenance:

The safety of pressure vessels and the need for regular maintenance are among the main challenges in this field.

Risk management:

Managing and mitigating the risks associated with the use of gases and liquids inside tanks is an ongoing concern.

The role of cylindrical tank in sustainable development:

Reducing environmental emissions:

Cylindrical pressure tanks play an important role in preventing the release of harmful gases to the environment. This reduction of environmental emissions contributes to sustainable development and environmental protection.

Flexibility in energy use:

These reservoirs have helped flexibility in the use of energy sources and have benefited from renewable and green energies.

Role in the transfer of harmful gases:

Ensuring energy security:

Cylindrical pressure tanks help to ensure energy security in various industries by safely storing gases.

Supplying raw materials for industrial processes:

These reservoirs participate as the main sources for gases needed in industrial processes and provide raw materials for these processes.

Challenges and solutions:

Technology and engineering development:

To face the challenges and improve the performance of pressure vessels, there is a need to develop advanced technology and engineering in accordance with international standards.

Natural resource management:

Considering the role of these reservoirs in the transfer of gases effective in energy production, effective management of natural resources and efficiency in the use of gases is vital.

Conclusion

In this article, we examined the role of a cylindrical tank. Cylindrical pressure tanks are important as one of the main tools in various industries including oil and gas, petrochemical, and gas industry. With safety features, the ability to transfer gases and liquids in large volumes, and a direct impact on the safety and productivity of the industry, cylindrical pressure vessels play an important role in industrial progress and development. Accordingly, paying attention to safety, regular maintenance, and updating technology in the field of these tanks is of particular importance.

Petrosazeh Company produces all kinds of fixed equipment including cylindrical tank, spherical tank, etc., with two decades of activity in the field of fixed equipment, it designs, supplies, manufactures and implements fixed equipment and always strives to provide the highest quality in its products. And he is proud that he has cooperated with large groups and companies in the oil, gas and petrochemical industry during all this time.