Before building the pressure tank, its design should be done according to its performance. Pressure tank design is a complex technical and engineering challenge that requires detailed details and complete knowledge of various parameters. In this article, more details will be discussed in the necessary steps and parameters to start pressure vessel design calculations.

Determining the volume of the pressure tank

First, according to the different needs of the fluids used in the tank, the required volume should be met. This volume determination is not only based on the amount of fluid, but also according to time requirements and other related factors.

Working pressure specifications

Determining the working pressure is one of the most important steps in the design of pressure vessels. This pressure can take into account the effects of normal pressure or special pressure that may occur in certain conditions. Also, how the pressure changes over time should also be considered.

Compatibility with temperature conditions

Different fluids work optimally in certain temperature conditions. Therefore, the tank must be able to adapt to various temperature conditions. Determining the freezing and melting points of fluids is also very important.

Check the surroundings

The environmental conditions around the tank should also be considered. Factors such as wind speed, the possibility of an earthquake, and the effects of weather conditions on the operation and strength of the reservoir must be carefully examined.

Use of standards and criteria

The design and construction of the tank must be compatible with relevant industry standards and regulations (including ASME BPVC). This includes things like tank wall thickness, material selection, connections, and welding methods.

Simulation using software

For detailed calculations and advanced simulations, the use of various software including ANSYS, COMSOL Multiphysics, SOLIDWORKS, MATLAB, PV Elite, Compress, and Caesar II provide extensive facilities in various fields. These softwares allow engineers to perform detailed modeling, fluid flow analysis, heat transfer analysis, and fluid mechanics analysis.

ASME BPVC standard requirements

To ensure proper use of the ASME BPVC standard, the formulas and regulations in Section 8, Division 1 should be considered. These formulas are based on the design criteria of the pressure in the tank wall, the properties of the building materials, the working pressure, the internal diameter of the tank and other related parameters.

Final steps before construction

In the design approval phase, a complete report of design documentation, drawings and calculations is prepared and reviewed by responsible engineers or specialists. After ensuring the accuracy of the documents, a design approval certificate is issued.

Start building the tank

After receiving the design approval certificate, the tank construction process begins. At this stage, all relevant standards and regulations are followed in the stages of construction, inspection and tests.

Complementary: Increase accuracy with more in-depth studies

To increase the accuracy in the design, more in-depth studies including advanced flow calculations, conducting fluid mechanics (CFD) experiments, and using advanced structural mechanics models can be useful. Also, new technologies in the field of tank monitoring and control help to improve their performance and safety.

Conclusion

Pressure vessels require accuracy and full knowledge of all the details related to the design. Implementation of the introduced steps along with the use of advanced technologies and modern software can lead to a safe and compliant design. On the other hand, increasing accuracy with additional studies and the use of new technologies will help to improve the performance and safety of pressure vessels.

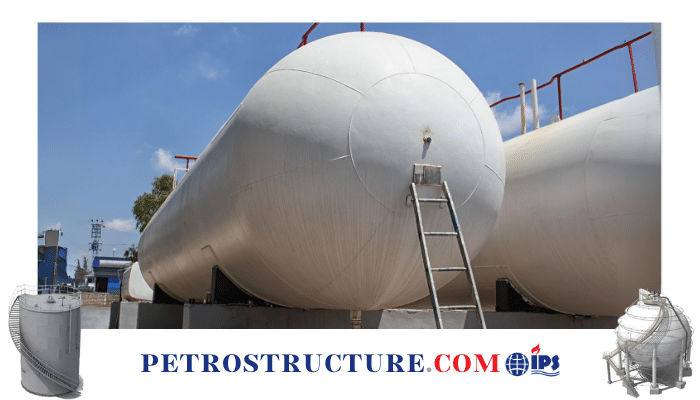

Petrosazeh, a producer of all kinds of pressure tanks, cylindrical tanks, spherical tanks, all kinds of fixed oil and gas equipment, fixed and rotating equipment, has always been with and synchronized with large industries in the oil and gas industry and companies active in this field. He has always been trying to be able to take a big step in the direction of our beloved country through the precise manufacturing of quality products.